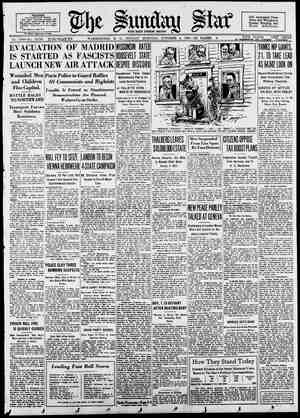

Evening Star Newspaper, October 4, 1936, Page 57

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

Stage and Screen Part 4—8 Pages he Sundiny St WASHINGTON, FEAT Do C, SUNDAY URES MORNING, OCTOBER. 4, 1936. ¥ mF MAKING BIG GUNS FOR AMERICA’'S NEW BATTLE FLEET Greatest Naval Equipment in History of Country Rushed by Thousands of Expert Gun Mechanics, in Workshop Which Is Carefully Protected. By John L. Frazier. G faces a smudge of smut, their eyes pinpoints of light; acrid fumes of burning ore, roaring blasts of flame, enormous trays of sand, molten metal, huge cranes, giant ingots of steel, rings, slabs—the “bark- ing dogs” of Uncle Sam’s new | Navy in the making. Under the expired ireaty terms with Japan and Great Britain, there is springing forward at the hand of Navy officials in Wash- ington today the greatest battle fleet ever conceived of by the United States. Day and night, thousands of expert naval gun mechanics are laboring to bring into existence mighty “growlers” to adorn the decks of these| ships, as they slip down their | waterways to the sea, and to belch forth, in case of war, fire and destruction to the enemy. The greatest naval gun fac- tory in the United States is at Washington, D. C., right under the eyes of the Navy. Here, guarded by a high brick wall, only recently thrown around the naval works, and sailor lads armed with service revolvers always on duty ;t the gate, naval guns are built. Here the rough forgings of naval guns to be are received from commercial con- cerns and, on giant turning lathes, shaped into mighty de- fenders. Here are molded from enormous steel slabs. breech blocks and companion . pieces which, later fitted together, form the firing end of the “Big Berthas.” NOMELIKE figures, their | IT IS like entering Vulcan's' workshop to go into the naval gun factory. Here are mighty! | electrical cranes, creeping along| overhead with tons of fighting | steel in their jaws. Here are 60- foot “growlers” tamely submit- ting to the purring softness of |steel tools, operated in the mouths of Jong, snakelike spirals. These giant guns are built up as a series of steel cylinders tele- scoping each other and shrunk on. In all there are four types of these cylinders—the liner, the tube, the jacket and the hoop. There may be several jackets and hoops to make the guns mighty and strong. It all de- pends upon the size of the gun. (1) A striking view as the big guns of the United States battle fleet fire a broadside during maneuvers in the Southern Pacific. Naval Academy are getting practical (3) Forging a three-ton billet. gunnery. (2) These middies of the United States information on (4) Molten metal coming from the big gun furnace at the Washington Navy Yard. California. (5) {\'ighl firing practice aboard the U. S. S. (6) Big guns of the Navy swinging into action. ~—Photos by Wide World and Harris & Ewing. | These different. parts are fitted | together, one upon the other, in |“hand and glove” fashion, by a process of expansion and con- traction. First, there is heating of a part in an electrical furnace to cause expansion, and then cool- | same process that caused it. The mighty 16-inch and 18- inch guns, thus finished, consist each of a liner, rifled for fire like a small-bore hand rifle, a tube, several jackets and hoops. They are heaviest at the butt end, the ing to cause gripping—a grip-| ping so tight that nothing can/ loosen it save a reaction of the, sion from firing. The tube of one of these great guns is the first thing forged. It is full gun length. When it has been forged and is cool, the first jacket is made ready to go on. This has been expanded for the operation by heating in an elec- tric furnace. been slipped over the tube the whole is laid ‘aside to cool. This | cooling shrinks the jacket onto !the tube with gripping force. The tube and first jacket now |on, other jackets—as many as | called for—are made ready and slipped on in like manner, the first impact of the terrific explo- ! {Day and Night Shifts Producing Modern “Big Berthas”, Under Most Detailed Perfection of Methods in As soon as it has| being “tooled” on a lathe to a | fine smoothness to receive them. The jackets all on, the hoops | are now put on. These are | nothing more than steel hoops| after the manner of barrel hoops, | placed at points of great stress| during the firing. Their purpose is to give added strength to the| part of the gun that takes the|gun, between these operations,! gun at these points. The gun, | long tube of special alloy-steel is again “tooled,” now looks very much like a long telescope, ta-| pering by jump-offs from the big butt down to the small, slightly flared muzzle. 'THE last thing In the building- up process of the gun is the placing of the liner inside. This COMMUNITIES OF NAT < Demands Received Here for 24,000 Miles Additional From Local Officials and Special Delegations. By Vesta Cummings. IGHTHOUSE keepers, bankers, lawyers and lovers, Italians, - Hawalians and Eskimos—every one seems to want correspond- ence sent by airmail these days. Miles of domestic airmail service would be nearly doubled at once if the citizens of the United States had their way, according to Harllee Branch, Second Assistant Postmaster General, in charge of airmail. In his files today are requests for 24,000 miles of new airmail lines, ini- tiated by civic and municipal bodies, mayors, private individuals and air- plane operators. With delegations and committees arriving in Washington regularly to apply for airmail service through their communities, airmail is bound to be even more inclusive in the future than it is today, Mr. Branch says. About 29,000 mail miles are being flown in Ameérican territory, which includes Alaska and inter- island Hawail, and 26,000 miles of service extend to foreign countries— Mexico, the Philippines, China, Cuba, Canada and South America. The already the most extensive in the world, Standing in the way of airmail ex- pansion today is the $500,000 deficit | on airmail this fiscal year, according to Mr. Branch. The deficit was ac- cumulated when the Interstate Com- merce Commission raised rates on cer- tain lines, adding from $200,000 to $300,000 expense to the post office, after Congress cut the appropriation requested, $12,500,000, by a quarter of a miliion, HOWEVER. representatives of the post office will be parked on the Capitol steps when Congress con- venes in January, Mr. Branch. says, in hopes of having this deficit made up_ by special legislation before the end of this fiscal year. Curtailment of scheduled airmail service during the Spring and early Summer months of 1937 will be.inev- itabile, if the deficit is not met with additional funds, and will inconven- | jece businesses that have learned to depend on swift letter carrying. In the operation of several sections of ‘Unncd States mail-flying service is phnclteuuuuolmmxullfl ‘bulke of flying envelopes ;would cease for & time, affecting the efficiency of the service. 'y ION IN RACE FOR NEW sTaking on the mail at Kansas City. ‘While some, of the proposed- new routes are worth consideration,” Mr. Branch says, others m‘o close to trunk airmail lines that trains can | distribute the mail as rapidly as a a special feeder company. “Every town in the United States | | thinks it imperative that airmail |planes land at an airport,” Mr. | Branch explains. “A great many of | these petitions may be granted ]eventullly. although our policy since annulment of all airmail contracts, after a controversy about rates more than two years ago, is to develop the existing transcontinental and coastal trunk lines, without dissipating funds on feeders, until a trunk system is fully developed.” In most instances, the north and south connecting lines follow natural irade routes and may themselves be termed trunk lines. Too rapid growth under present appropriations would penalize com- panies already flying the mail, Post Office personnel believe, and in some instances expansion must follow navi- gation aids not yet installed in cer- tain sections — light beacons, radio beam equipment and weather stations. UNeER existing regulations some feeder services might find it too expensive to operate, espe- cially in cases where one man with s plane, flying pessengers between AIRMAIL LINES Financial Requirements Offer Obstacles, While Policies in Relation to Trunk Lines Are Important. | their mail contracts and go back to | the stage coach lines. two points, wishes to carry the limited | quantity of airmail between those cities in addition to his small passen- | ger service. At the moment, pilots | are required to wear uniforms and keep uniform systems of accounts, usually requiring extra help. How- ever, bids for flying mail go to the lowest competitor, who must fly the route for three years under the terms of his contract before he can present himself before the Interstate Com- merce Commission asking for a change of rates, a protection against deliber- ate underbidding. Mr. Branch points out that the growing pains of so great an under- taking as transporting by air 15377~ 469 pounds of mail in 1936, an in- crease of more than 2,000,000 pounds | over 1935, are bound to be trouble- | some. Referring to 1934, when air- mail contracts were annulled, he said | that he recently ran across the record | of a postmaster of the last century who was so annoyed with the rail- roads that he threatened to cancel Besides lack of appropriations, ex- tension of feeder service is prevented, for the time being, by the fact that Dealing With Titanic War Forces. slipped into the barrel of the gun by the same old expansion method. When the assembled barrel has cooled, it is ready for the next operation—the most delicate of all in the shop—that of boring and rifling it. For this job the gun is hoisted by one of the giant electric cranes, running everywhere throughout the shop, to a posi= tion on one of the great boring lathes. These cranes, capable of lifting 380 tons, pick up a mam- moth gun as though it were a toothpick and swing it into posi- tion. In the lathe, a long, slender, snakelike screw, with a cutting die on its end, bores its way slowly up the long barrel of the gun, cutting out for itself a vel« vety path of smooth steel, the dixzxensions of which have been speécified. This accomplished, rifling of the barrel takes place. It is virtually the same operation as the boring one, except that a different type of cutting tool is used and one that is counterbal- anced to make sure that no “wabble” in the cutter takes place. This rifling gives to the fired shot a twisting motion, causing it to penetrate more deeply the object it hits. WHEN the barrel has been rifled, it is turned over to experts for detection of any flaws that might be in the cylin- drical interior. The flaws can be pockets in the metal uncov- ered by the rifling, after the bor- (Conunued‘on Page Six.) Conlhmed‘on Page Seven.)