Evening Star Newspaper, November 30, 1930, Page 100

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

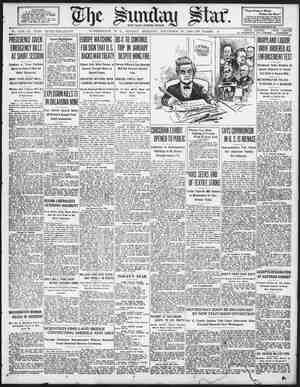

Subscribers enjoy higher page view limit, downloads, and exclusive features.

12 THE SUNDAY STAR, WASHI MARVELS IN CONSTRUCTION Here Are Many Hitherto Unrevealed Details About the United States Navy’s ZRS-4, the Akron, Which Will Be an Eighth of a Mile Long, When Cothleted May, 1931. n o F-.v:.l P Air Tank ‘l},z Drive S S‘fl;'vl Radiator Dr. Arnstein and Lieut. Settle, on the ground, watch as Dr. Klemperer demon- strates the unique propeller mount. The drawing shows how engineers inside ghe ship will regulate the tilting propellers to push up, down, forward or back. By TIsrael Klein. ADUALLY outlining itself under the roof of an immense building at Akron rises the skeleton of what will soon be the world’s greatest rigid air- ship. It is the ZRS-4, to be christ- ened the Akron, named after the city of blimps and tires, wherein may be found some of the greatest airship minds and the greatest airship factory in the world. Today, hundreds upon hundreds of plumb lines are hanging from as many points 15 to 150 feet overhead. Men, like monkeys, are scaling tall ladders, clinging to beams and girders, riveting joints, securing wires, fitting sections, hammering, measuring, always checking and testing. Weights in masses from 100 to 1,000 pounds hang in several parallel lines from ropes over pulleys high above, holding taut the huge bulk of silvery metal. Huge frames of duralumin girders, some as wide as 133 feet, are being laid out on the ex- tensive floor. Overhead men on movable platforms are riveting other frames or rings in place, con- necting them with horizontal girders of dura- lumin, bracing them with taut wires and grad- ually bringing the huge 6,500,000 cubic foot airship into shape. N a factory nearby other workers are stamp- ing out and preparing more girders for this tremendous aircraft, laying out small sections of the ship between blocks and clamps on the floor, preparing blueprints for further details, studying the thousands of those already drawn, testing parts, collecting data, constantly seeking advice that should help make the Akron the best, sturdiest, safest and most durable airship in the world. The ship is being built at Akron in a dock especially erected for its construction for the United States Navy by the Goodyear-Zeppelin Corporation. By May, it is expected, its great hulk will nose its way out of the immense dock to take the air for the first time. Soon after, if present arrangements remain unchanged, its sister ship. the ZRS-5, will begin to take form and 15 or 18 months thereafter take its place beside the Akron in the U. S. Fleet. This airship squadron will give the U. 8. Navy the world’s greatest, most unusual and most far-reaching possibilities for maneuvering in the air and will make the United States supreme in thisz class of naval vessel. The Akron alone, in its dimensions, its equip- ment, its range and usefulness, will far surpass any other airship now afloat. It will include such novelties in design, construction and operation as will keep its type useful in com~ merce and warfare for many years to come, even though it will without doubt soon be sur- passed in size by future ships. CONSID!.'R for a moment its outstanding features: 1. Nearly three times the size of the Los Angeles, the U. S. Navy's present airship; twice the size of the Graf Zeppelin, and far greater in size, power, speed and range than Great Britain's R-100 or its ill-fated sister, the R-101. 2. Not much longer than the Graf Zeppelin, but more bulky, to give it greater strength and load-carrying capacity. 3. Eight powerful engines, totaling nearly 4500 horsepower, three more than the Los Angeles or Graf Zeppelin, two more than the British ships. 4. Radical departure in propulsion by means of tilting propellers, giving the ship an optional upward and downward push in addition to forward and astern. 5. Twelve compartments, having as many gas cells, ranging in size from 80,000 to nearly 1,000,000 cubic feet, and totaling 6,500,000 cubic feet. 6. Helium, non-inflammable, second lightest gas known, as its lifting gas, enabling place- ment of the engine rooms within the hull and so presenting an almost unbroken streamline for greater speed and easier accessibility to the power plants. 7. Equipped with the greatest battery of rapid-fire guns and other weapons ever to have been put on an aerial vessel. 8. Carrying within one of its 12 bays, or com- partments, a hangar accommodating five air- ¢ planes of the pursuit or observation type, with a unique trapeze arrangement and hatch whereby the planes can be launched or taken aboard while the mother ship is under way. 9. Will climb faster than any airplane, and will cruise without landing or refueling as far as 9,200 nautical miles, equal to nearly 11,000 land miles, double the range of the most modern surface scouting craft. 10. Could carry if built for commercial pur- poses up to 100 passengers besides a crew of 50, giving its guests all the accommodations re- quired for their comfort and pleasure. 11. So securely built that its engineers say it will be able to buck a sudden storm having an upward air speed of 60 feet a second while it is flying at full speed ahead. 12. High-powered radio equipment covering It is so symmetrical that it doesn’t look" large in this picture. But observe the size of the men on the top of the scaf- folding beneath the Akron’s frame at the right center of the picture, and com- e its huge bulk with objects on the floor of the dock. every conceivable facility for secret transmission and reception of messages by telegraph and facsimile reproductions over distances at least one-third the way around the earth. OR more than 10 years before even the first rivet had been “squeezed” on the ship’s skeleton plans, preparations and research had been going on. In fact, right after the war the U. 8. Navy started planning the type of ship that the Goodyear-Zeppelin Corporation today is building for it. Early in the 1920's commercial interests headed by Paul W. Litchfield, Goodyear’s president, concerned themselves in the con- struction of such ships that would surpass in size even the Shenandoah, which the Navy was only beginning to build, or the Los Angeles, which Germany at the time had only on paper. With American business men interested, de- velopments proczeded fast. Goodyear entered into contract with Luftschiffsbau-Zeppelin in Germany for the American patent rights on Zeppelin construction, brought over by Dr. Karl Arnstein, with a group of leading German Zep- pelin engineers, among them Dr. Wolfgang Klemperer, set them to work on the design of ships of 5,000,000 to 15,000,000 cubic feet ca- pacity, won through their research two airship design competitions set by the Navy, and as a result got the job for construction of the two forthcoming Navy airships, ZRS-4 and 5. The size, design and other features of these airships are the product of over three years’ detailed research and experimentation con- ducted at the Goodyear factory by Dr. Arnstein and his associates. From 1924 to 1927 these scientists drew up hundreds of plans, including innumerable ships with different characteristics, tested various forms of girder construction, tried out thousands of different joints and studied every minute detail of construction in the most painstaking manner. EVEN the dock in which the Akron is being erected is something new and unique in building construction. A huge steel structure nearly 1,200 feet long, 325 feet wide and 200 feet high, with not a single interior support in it. Big enough to accommodate not only the huge airplane now being built in it, but another of 1,000,000 cubic feet size and a few odd bal- loons, blimps and airplanes besides. The dock alone cost $2,500,000, but it will be available for construction after the naval airships are completed of other Zeppelins twice the size of the Akron or the ZRS-5. While the dock was being built at one end of the municipal airport at Akron, its length in line with the prevailing winds, Dr. Arnstein’s men in the plant nearby were continuing their research and experiment, and beginning actu- ally to stamp out beams and other sections of duralumin in preparation for the actual con- struction of the ship. o The staggering complexity of the fr which shows riveters at work o Girders of all types were tested for strength, in tension, compression and bending. Joints of innumerable sizes and design were put under loads simulating actual conditions. Wire ter- minals were devised to eliminate excessive strains and breakings and to prevent chafing and tearing of the gas cells. The scope of research was almost unlimited. It is still going on. Sixty tons of duralumin, light alloy of alumi- num, copper and manganese, are going into the hull of the Akron. Yet this is one-third the weight that would be required for a similar structure of mild steel. The metal's stiffness is enhanced considerably by turning up, or beading, the edges where parts have been stamped out of it. LEVEN main “frames,” or polygons, ranging from 24 to 36 sides, act as chief transverse supports of the ship. Each of these frames is actually two parallel rings joined by longitudinal girders and connected in criss-cross - fashion with a third interior ring. The result is a triangular passageway all the way around the ship large enough for a man to traverse comy fortably. This triangular section construction affords maximum rigidity. Three intermediate frames are placed at equal intervals between every two main frames, and all are joined by horizontal girders at each of the 36 joints, thus forming a rigid and stable hull structure. A steel wire network connects 18 joints of the interior ring of each main frame, forming a bulkhead, or wall, between two adjacent cells of lifting gas. Thus two adjoining main frames with their wire bulkheads form a compartment, or “bay,” in which is a gas cell, one of 12, ranging in size from 80,000 cubic feet at the bow to nearly 1,000,000 cubic feet amidships. A new departure in gas-cell, construction is made in the Akron by using a rubberized or gelatinous latex, an artificial fabric which has been found a good substitute for the expensive “gold beater’s skin,” made of the lining of cows’ stomachs, heretofore used. %