The Nonpartisan Leader Newspaper, January 12, 1920, Page 5

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

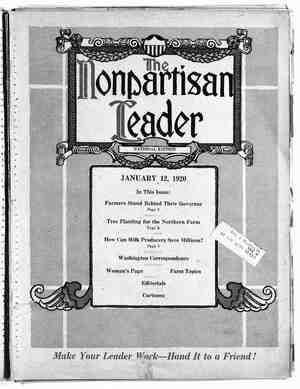

i R ~-——-g~System of agencies to re-, How Can Milk Producers Save Millions? The Plan of J. J. Osterhous, North Dakota State Dairy Commissioner, to Eliminate Wasteful Methods ~BY E. B. FUSSELL AST week’s Leader told of the investigations of J. J. Oster- hous, state dairy commissioner of North Dakota, showing loss- es of $3,565,000 a year by North Dakota dairy producers on a production of 25,000,000 pounds of butterfat. This loss was made up of $1,000,000 of stor- age profits, now going to speculators, which should be saved for the producers; $1,000,000 lost through failure to market a good and stable quality. of butter; $1,000,000 profits made by butter manufac- turers on the “overrun” in excess of necessary man- ufacturing and marketing costs; $500,000 lost on wasteful collection systems; $50,000 lost on ship- ment of partly filled cans and $15,000 on express charges on water. Most of these losses are sustained by other states besides North Dakota. -Many states with greater dairy production have much higher losses because of the greater volume of business transact- ed. So the Osterhous investigations are of interest to dairymen everywhere. Mr. Osterhous does not content himself with finding fault with the present system. Pointing out the present losses, he brings “forward also a proposal for eliminating them. He says in his re- port: “It has been shown that the producer sustains a loss of 10 to 15 cents on each pound of butter marketed. It now becomes my purpose to show how this loss can be stopped and future losses avoided. “The system advocated is one that will increase interest in dairying and result in more efficient and economical production. It will make possible the uniform dis- tribution and utilization within the state of the by-products of our state mills, put a stop to’ the evil practice of permitting other states to build up their soil fertility at the expense of ours and remove the handicap which has enabled other states which could get our mill prod- ucts at less cost than our own farmers whe raised the wheat, thereby forcing production costs of North Dakota dairy products higher than they were elsewhere. The system to be outlined will encourage immigration into this state of a class of farmers who want to practice dairying and who are familiar with efficient pro- duction methods. When steps are taken in this state which will decrease the cost of pro- duction and at the same time return to the producer a great- er percentage of the sale price of his product—then dairy pro- ducers can not afford to remain away from North Dakota. STATE MARKETING SYSTEM IS PLAN “All this and more can be accomplished by providing for ceive the raw marketable dairy product, to manufacture it in- to butter, to store part of it and finally to put all of it on the wholesale or retail market. This system can also distribute to the farmer feed from the state-owned mill, silos and other material. It is the duty of the state to provide, oper- ate and manage these agencies. “The system of agencies shonld be made -up as follows: “One central selling agency and cold storage plant. “Ten or 12 centralizer cream- eries. : “Four hundred to 500 cream stations. “The cost of providing this system, distribfition of costs, activities and functions may be outlined as follows: “Central selling agency and cold storage plant: “Cost of plant, $250,000; capital, $750,000; total, $1,000,000. “Activities—To receive all butter from 10 or 12 creameries, inspect grades and labels for composi- tion and quality. To sell butter to domestic whole- sale trade and foreign or export trade. To store butter during period of heavy production and low prices, selling same when production is light and prices high. To set price paid for butterfat at creameries. To keep records of entire system. To buy equipment and supplies for cream stations and creameries. To handle poultry, eggs and other produce bought at stations and creameries. To buy feed, silos, ete., to fill orders placed by cream- eries. “Centralizer creameries, 10 to 12 in number: “Cost of plants (10 at $75,000), $750,000; cap- _ ital ($50,000 each), $500,000; total, $1,250,000. “Activities—To receive all cream bought at each of its 40 to 50 cream stations and grade and test all cream received. To manufacture butter of uni- form quality and composition under direction of a central agency. To keep churn records. To manu- facture ice cream and by-products of creamery industry. To have direct control over cream sta- tions. To receive eggs, poultry, etc. To act as distributing agency for feed, silos, etc. “Cream stations, 40 to 50 for each creamery, 400 to 500 total: “Cost of plants (500 at $1,000), $500,000; capital ($500 each), $250,000; total, $750,000. “Activities—To buy cream on basis of quality and butterfat content. To be in charge of a sal- | NOT YET BUT SOON—MAYBE I — : ~—Drawn expressly for the Leader by W. C. Morris. The dissolution of the “Big Five” packing combine is a hopeful sign of the times. - What would be a great deal more hopeful, Morris thinks, would be for Uncle Sam to ‘take the place of the Armour-Cudahy-Swift crowd and operate the= packing plants 'fo:‘ggrvice rather than for profit. aried person, competent and under bond' t6 grade and test cream correctly. To be the center of all activities having for their purpose the general de- velopment of the dairy industry-in the community. To be provided with facilities for preventing de- terioration of cream received. To receive and for- ward poultry, eggs, ete., to its central manufactur- ing plant. To act as the local distributing agency for feed, silos and other materials used on the farm in the production or handling of dairy prod- ucts. “The total cost of putting this system into opera- tion and financing the same amounts to $3,000,000. This, it will be noted, is more than a half million dollats less than the losses which are annually sus- tained through the present system of marketing dairy products. It therefore seems not only ad- visable but imperative that serious attention be given and early action taken to correct existing ills.” STATE DAIRY DEPARTMENT IS ALREADY DOING BIG WORK And this serious attention, it may be added as a postsecript to Mr. Osterhous’ report, is being given to the dairy situation in North Dakota. Grain grow- ing is North Dakota’s biggest industry still, and the present administration is working, first of all, to eliminate some of the $55,000,000 annual waste in this industry. But dairying is growing in North Dakota. During the last year the value of the dairy products was 25 per cent of the value of the grain crop. And as soon as the big state mill at Grand Forks is in operation and is turning out cheap feed for the stockmen, the dairy industry will take another boost. And by the time the next North Dakota legislature meets in regular session there is reason to helieve that the organized farmers will be ready to tackle the problem of the millions:lost in the dairy industry as fearlessly as they tackled the problem of the millions lost in grain. Already the North Dakota legislature and the state dairy department have taken the first steps toward reducing losses to the dairy producer. Under senate bill 139, passed by the regular session of the 1919 legislature, 1862 separate tests of cream samples had been made up to a short time ago. In 747 cases it was found that ‘cream buyers had been giving farmers credit .for a smaller’ percentage.-of butter- fat than the official test show- ed. In every case the farmer was informed of this fact and the cream buyer instructed to issue an additional check. Besides securing these re- funds, however, the official test- ing has made the buyers much more careful in all their work. In the first 592 tests made, for instance, cream buyers were found to have cheated farmers of 748 pounds of butterfat by under-grading. But on the last 693 samples tested the butter- fat secured by créam buyers without proper payment was found to amount to only 139 pounds. Individual producers in scme instances have been able to sell direct. Senator A. A. Leider- bach, for instance, sells his entire output to a Bismarck ' restaurant. Although he has to ship his cream more than 100 miles at a high rate both he and the buyer make a big saving. Such men as have been able to deal directly with the consumer have seen the tre- mendous savings that might be made by all milk producers by economical marketing methods. Such methods North Dakota hopes to adopt at the earliest possible moment. G2 < eerd