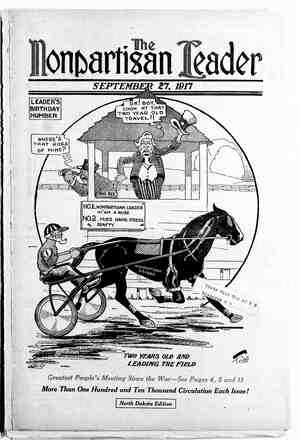

The Nonpartisan Leader Newspaper, September 27, 1917, Page 8

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

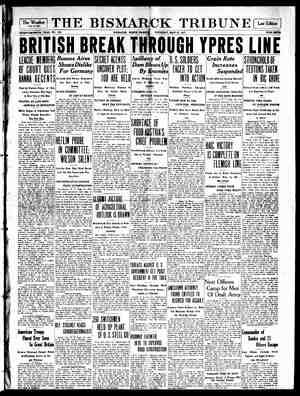

Sugar Beets and Sugar Beats The Manufacturer Gets the Sugar, the Grower Gets the Tops, is the Way It Seems to Work Out in Montana | Factory of Great Western Sugar company under construction at Missoula, Mont. to be finished about October 1 at a cost of $1,500,000. It is reported that the com- pany expects this factory to pay for itself on the profits of its first two years of operation. BY E. B. FUSSELL PRICE guarantee for farm products, in advance of the planting season, is the latest cure-all offered ' by ' parlor economists for the ills of the farmer. There is one farm product of the United States that has been grown for the last 12 or 15 years in half of the western states with a fixed price guaranteed to the farmer each year before he sets a seed in the ground. This is the sugar beet. To see just what effect the price guarantee syetem. has had the writer recently made a study on the ground of the beet sugar _ sitwation in Montana. Montana was chosen because it offered two factories, one in a new section at Missoula, just -being brought into sugar beets, and the other, at Billings, in a section where the growers have had a dozen years experience.” 4 Missoula was visited first. The Great Western Sugar company is put- ting up a $1,500,000 factory there which will be finished about October 1. The Great Western, with headquarters at Denver, owns 16 factories, including three now under course of tion. Ten of these are in three in Nebraska, two in Montana and one in Wyoming. The company in the last year paid all its regular dividends, saved $4,500,000 to put up the three new factories and invested a big surplus in Liberty bonds, and it would appear, with all these profits, that there should be plenty to go around to the sugar beet grower, too. MISSOULA BEET CROP WILL NOT BE HEAVY Colorado, But I was more or less surprised to find, at Missoula, that the beet grow- ers weren't particularly = optimistic. While the factory is equipped to handle 800 tons a day for a 100 to 120 day season, owners of only about 3500 aeres have signed up contracts and put in beets and Manager F. A. Wilson estimated that the crop would be only about 30,000 tons, or about 81, tons to the acre. This will mean that the Missoula factory will have only enough beets to run a little more than a month. The contract which the sugar com- pany offers the beet growers covers practically everything. The growers agree to buy seed from the company at 10 cents per pound, sowing 15 pounds to the acre. The company also arranges for contract labor for 'the farmer to do the hand work of the sugar fields, at $22 per acre. The farmer plants the seed with a four- row drill, irrigates (all the western beets are grown on irrigated land) lifts the beets with a plow and hauls them. The contract labor consists principal- ly of Russian-Germans imported by the sugar company. These are mem- construc- bers of German families who about 15 years - ago completed 200-year labor=» contracts, signed by their ancestors, in Russia. The whole families work in the beet fields from earliest dawn to dark, 'and sometimes after dark ‘with a lantern.. They get $11 an acre for the spring work, which consists of block- ing out the thickly planted beets-with a hoe, thinning by hand and two hoe- ings, and another $11 for the fall work, which consists of pulling and topping the beets and throwing them into piles. The ranks of the Russian-Germans have been added to by the importation of .some Mexicans and Japanese in re- cent’ years. A WHAT THE FARMER GETS FOR HIS BEETS Aside from this contract labor, the sugar company officials say, one farm- er should be able to do the work of putting in and harvesting 40 acres of sugar beets, except that if he lives bonic acid and sulphur gas are intro- duced as further purifying agents. Then the solution is. evaporated until it is a thick syrup. Next the syrup is boiled. As it boils the ‘*grain” forms gradually. This is -the sugar. The liquid that is left is a thick molasses. The mixture is taken to the centri- fuges, which operate on the prineiple of a cream separator,-and the sugar is separated: from the molasses or syrup. Then the molasses is sent back for re- refining, which resulls in the extrac- tion of more sugar. If the 340 tons of sugar beets sold by the grower contain 12 per cent sugar there is an actual content of 81,- 600 pounds of sugar. However, process of manufacturing allows the extracting of only about 85 per cent of this, or 69,360 pounds. 3 But there are other products than the sugar. The molasses or syrup product and the pulp of the sugar beet, generally dried after all the sugar pos- Guaranteed prices, fixed by the handlers of farm products, for their own advantage, don’t do much good. It is about time the farmers had something to say about fixing the price on their own product. some little distance from the railroad, he will have to have extra help in hauling. The growing season is 130 days. The contracts with the grower speci- fy the price he will receive for the beets. The price specified for this year’s crop is $6.50 per ton for beets testing from 12 to 14 per cent sugar, with an additional 123, cents per ton for each additional one-half per cent. Now the average crop in the vicinity of Missoula this year is likely to be about 81 tons to the acre. Let us see what the owner of a 40-acre farm would get out of this crop, if he pro- duces 12-14 per cent beets. He would have 340 tons and the price he would receive from the sugar company for this product at $6.50 per ton would be $2210. : HOW THE BEET SUGAR IS MANUFACTURED ‘What happens to the $2210 worth of beets after the factory gets them? First they are cut up into fine shreds, . called “cosettes.” Then hot water is introduced and by a process of diffu- sion most of the sugar .is dissolved from the cosettes. The solution is mixed with lime to reduce alkalinity : (the beets take a great deal of alkali out of the soil) and then filtered. Car- sible has been extracted, still contain the 15 per cent sugar that it has been impossible to extract. Mixed they make an excellent cattle food. The pulp is generally sold dry, every ton of beets making about 100 pounds of dried pulp, while the syrup amounts to about 4 per cent of the weight of the beets. The pulp and the syrup are sold back to the farmers. . Eventually,. the farmers buy a good deal of the sugar back, too. THIS IS WHAT THE SUGAR COMPANY GETS ‘What are the prices of these prod- ucts? When the writer was in Mis- soula the farmers were paying for their sugar $9 per 100 pounds or 10 cents a pound straight if they bought in- smaller quantities. The sugar com-~ pany is. preparing to sell the dry pulp back to the farmers at $20 per ton and the syrup at $25 per ton, So this is what the sugar company gets out of the 340 tons of beets that it buys for $2210: Sugar, 69,360 1bs. ........$6242.40 - Dry pulp, 34,400 1bs. ...... 340.00 Molasses, at least svve.ou.. 200.00 Potal . T e s sns vesr $67827540) But this is taking the minimum amount of sugar, 12 per cent. If Profits of the American Sugar Refining company, one branch of the Sugar Trust, were $2,991,- 465 in 1915 and $9,736,379 in 1916, an increase of $6,764,914 or 226 per cent in one year. Yet beet prices in Montana have increased only 30 per cent in 12 years. Is it any wonder that the sugar companies are able to buy Liberty bonds, and that the farmers have to seratch for enough money to put in next year’s crop? L PAGE EIGHT the - the beets contain up to 14 per cent of sugar (for which the company pays the same price as for 12 per cent beets) the company will get $7282.80 worth of sugar and with pulp and syrup the total: value of the product will be $7820.80. - - ‘This from the beets which the farmer sold for $2210!- . 3 It can easily be shown that produc- ing 81 tons of 12-14 per cent beets to the acre, the grower around Missoula will dctually be losing instead of gain- ing money. His own labor with a team at $8°a day for 130 days will be worth $1040, extra labor on the contract sys- tem at $22 per acre will be $880 more and hauling at even 50 cents per ton would $170, Add to this $60 for seed and you have $2150 without counting what the farmer pays for his water or any interest on the value of the land, and the chances are that he is paying 8 per cent interest on a mortgage that covers half its value. . WHAT DOES IT COST THE BEET GROWER? - I have purposely left out any con- sideration of interest on investment in calculating the charges against the beet grower at Missoula. Land values dot not appear to be stabilized in the Bitter Root valley; prices have been put clear up to $250 or $300 or even more an-acre when it was claimed that the land was good for apple growing; however, a considerable body of state land under an irrigation ditch was sold the other day for less than $100 an acre. For other reasons it is hardly fair to base conclusions on Missoula, where they are just starting in with beets. Let us look instead at the situation at Billings, where they have been grow- ing beets for a dozen years now. The Great Western has a factory there with a capacity of 2100 tons a day. The average yield around Billings is 10 to 1034 tons per acre. The growing of sugar beets, real estate men say, has been a powerful influence in stabilizing land values. They calculate the value of a piece of land around Billings now in the terms of the number of tons of beets it will produce. = The average valuation of land, I was told by the secretary of the commercial club, runs from $125 to $140 per acre. Taking the lower fig- ure, the costs of producing sugar beets on 40 acres of land may be summarized about as follows: Interest on land at 8 per cent $ 400 Seed at $150 per acre ...ee.. 0 130 days with teams at $8 .... 1040 Contract labor at $22 per acre 880 Extra hauling at 50c per ton 200 —_— Total COSt .eessessesasess.$2580 Forty acres producing 10 tons to the acre and selling at $6.50 per ton will e YAk