The Nonpartisan Leader Newspaper, September 6, 1917, Page 9

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

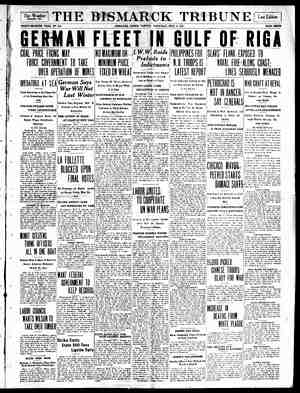

¥ J b} ~ Flax for Seed and Fiber Eastern Trust Casts Eyes Toward New Northwestern Industry,° Montana Flax Fiber Plant Factory of Northern Flax Fiber company at Conrad, Montana. This factory cost abput $50,000 and may be taken over as part of a $5,000,000 linen trust plant for producing linen from Northwestern flax. BY E. B. FUSSELL IBER flax promises to have a big future in the United States after the war. At least that is the view of the men who are in the flax fiber game, such as' the Northern Flax Fiber company, which has a fiber factory at Conrad, Mont. Up-to-date, most flax growers of the Northwest have raised flax for the seed alone. The fiber has largely gone to waste. Growers who have made enough money off their crop to afford to buy a few linen handkerchiefs for themselves and their wives have bought linen from Irish mills, made from flax fiber from Belgium or Russia, In the future, probably, there will be more fiber flax grown here and farm- ers may be able to buy handkerchiefs made from their own product. The fiber flax produces both the seed and the fiber from which linen is made, ‘not so much seed as the seed varieties, but enough to make the crop well worth while if handled under proper conditions and under terms that will give the grower fair value for his prod- uct. - The Northern Flax Fiber company has operated largely on an experiment- al basis for the last two years. This’ year, however, its Conrad factory has contracted for the product of 1200 acres planted to fiber flax. This will produce from 2000 to 3000 tons of straw from which can be made from 300 to 500 tona of fiber. . SLIDING SCALE BASED ON PRICE OF SEEQ The company is buying straw from the farmers on a sliding scale contract. The price is based upon the average price of flax seed at Duluth during the month of September. The com- pany guarantees a price of $15 per ton, with an’ increase. if the price of flax seed is above $2 per bushel at Duluth The maximum price aliowed is $25 per ton, this to obtain if flax seed is more than $3 per bushel When last year’s crop was harvested the growers got only $15 per ton for it Most of them were disappointed and the company was able to contract for less acreage this year than it wanted However, it appears probable that this year the growers will get the maximum price of $25 per ton. The fiber strain of flax produces from five to six bushels of seed to the ton on irrigated land, as compared with 12 to 15 bushels of seed from the seed strain varieties. All the Montana fiber flax is grown on irrigated land. How much straw can be grown to -the acre depends 'upon cultivation, weather and, to some extent, upon luck. The ‘Montana agricultural college has raised as much as five and three-quarters tons to the acre. Some farmers have been unable to raise more than one ton. The- company guarantees one ton to the acre. The average is about two or two and one-half tons. BRITISH GOVERNMENT AFTER MONTANA SEED a The ‘company has been selling seed to the growers, charging:-them §3 per bushel. As practically no fiber flax . has been grown in this country there has been some difficulty in securing seed. Nesbit Rochester, superintend- ent of the company, showed the writer bills indicating that seed bought last .year in Canada after payment -of freight and duty, cost the company nearly $5 per bushel. This year’s crop, however, should provide the company with plenty of its own seed. There is a lively demand for this seed from others than linseed oil manufacturers. The British government is anxious to take over the entire seed production of the Conrad plant this year. Fiber flax is harvested earlier than seed flax, before the seed has thor- oughly ripened, which explains, in part, why the seed production is less. This prevents the fiber from becoming too dry. After the straw is received at the factory it is first put through the “ret- ting” process, which in reality consists in rotting away the outer covering. Then it is put through machines which break off the remainder of the outer covering of the straw, this be- ing done with a series of rollers. FIBER USED FOR ROPE, OAKUM OR LINEN The remaining treatments are all for the purpose of improving the quality of the fiber., How much further treat- ment is given the fiber depends upon the use for which it is intended. Comparatively Iittle treatment is needed to supply fiber good enough for cord or rope. Much of the product of the Conrad factory, thus far, has been of comparatively coarse grade and has been shipped to rope factories in Cali- fornia. . Some has been used for oakum. However, the Conrad factory has shipped one carload of its better grade fiber to a linen mill at Dublin. This was since the beginning of the war and it took six months for the company to get a return on its shipment. The re- port showed, however, that it made a fair quality of linen. The best grades of Canadian fiber are now commanding a price of 55 cents a pound. The Conrad factory ex- pects to be able to get from 40 to 50 cents per pound for most of its product this year. If one ton of fiber, for which the company pays $25, produces six bushels of seed, worth from $3 upwards per bushel, and 300 to 400 pounds of fiber, worth from 40 to 50 cents per pound, it can be seen that the industry 13 a promising one from the standpoint of the manufacturer. INDUSTRY IS ONLY IN ITS INFANTRY “We are only making a beginning in the flax fiber business,” said Super- intendent Rochester to the writer the other day. “Europe is far ahead of us BOYCOTT FARMERS' FRIEND x The following item from the Kenmare (N. D.) Journal shows how some few business men are still blind enough to fight the farmers by withdrawing support from country papers that are supporting the farmers’ program and organization: ‘‘P. M. Cole don’t like the attitude of The Journal on matters pertaining to the Nonpartisan league, so this week he instructed his employes to cut out all business relations with this office, which has been done. As the stop order includes a general store, a bank, a lumber yard and an automobile agency, it means the loss of considerable business to the office; but we’ll just take a chance that we can exist without it, and continue to support the League, the same as we have in the past. We believe the principles as ad- vocated by the Nonpartisan league are right, that when enacted . into law they will prove of benefit to the people as a whole, and this being true, the League shall have our support regardless of the attitude of those who may be in a position to help or hinder us financially.”’ ’ Wisconsin With Real League Farmers Vote Unanimously to Drop Plan for Separate Organization y ‘Wisconsin farmers are united behind the National Nonpartisan league. At a meeting held in Milwaukee, attended by representative farmers from all parts of the state, it was decided that all plans for the organization of a separate league, distinct from the Na- tional league, be dropped, and that Wisconsin get solidly behind the plan to co-operate with the farmers of North and South Dakota, Minnesota, Mentana and the other states which are working on a single program. After some discussion, which straightened out misunderstandings between a group of farmers who were working on a separate organization, the vote for affiliation with the Na- tional league was unanimous. Although the League has had head- quarters established in Wisconsin for only a few weeks, remarkable work is being done. Beecher Moore, Wiscon- sin superintendent, told the Milwaukee meeting that nine out of every ten farmers who were asked to join, were coming in. The League already has more than 700 members in Dane coun- ty, with 86 members in one township alone- A state convention will be ar- ranged shortly to adopt a state plat- form. - Organized labor In Wisconsin, which received poor treatment at the hands of the recent legislature, is showing a lively interest in the League work, and the working men of the cities ecan be counted upon to co-operate with the working farmers in the next electiom, PAGE NINB because they have been growing fiber flax for thousands of years. “Everything depends upon the care that is given the flax from the time the seed is planted in the ground until the flax fiber is turned over to the spin- ning mills. There are big chances for improvements in our methods both in the fields, where the farmers are grow- ing the flax, and in the factories, where it is being handled. “After the war, when some of the ex- pert Irish and Belgian and Russian labor may be expected to come here, to show the farmers and ourselves some of the fine points, watch for fiber flax' growing in the United States to take a boom.” NEW LINEN TRUST CASTS EYES ON NORTHWEST That private capital is beginning to take an interest in the possibilities of fiber flax culture and linen manufac- ture in the United States is indicated by the organization recently of the Amerlin company (abbreviation for American Linen company), a Delawars corporation capitalized at $5,000,000. This company is now dickering with the Northern Flax Fiber company for its Conrad factory. It wants to link this up as one of a chain of factories, along with a big spinning mill at Be- loit, Wisconsin, so that this one com- pany will control the linen manufac- turing game in the United States, from the making of flax fiber up to the finished product. Montana is taking an interest in flax in other ways. Two tow mills have been organized recently, one at Havre and the other at Brockton. Both ex- pect to be doing business this fall. The tow factories can use ordinary straw from seed strains of flax, while the fiber factories can use only the fiber strain. The tow factories also have less manufacturing expense. On the other hand, their product, used largely for upholstering, brings only from 10 to 30 cents per pound, as against 40 to 50 cents for the fiber. . - A farmer should not expect to go into the business of raising fiber flax unless he is able to pay a good deal of attention to it. The followings are “Ten Rules” prepared by the Northern Flax Fiber company for the guidance of farmers who are working under their contracts: RULES FOR GROWERS OF FIBER FLAX 1. Select good land, free of foreign growth, with good drainage. 2. Plow at least six inches deep—fall plow if possible. . 3. Disc, harrow and float until well pulverized. The seed bed must be es- pecially fine. 4. Compact the field, with a roller if possible, then cross harrow. - 5. Plant one-half inch deep—do not exceed 1 inch. Sow 85 to 90 pounds to 'the acre, between April 20 and. May 15. - 6. See that the flax has plenty of moisture at all times and especially when going to bloom. 7. Harvest early—never allow to en- tirely ripen as for seed flax. 8. Shock in open rows, morth and south, about 12 bundles to a shock. Do not let it lay. 9. Stack, if not delivered as soon as cured. 10. Make good bundles when har- vesting and do not tear open in bhand- ling. 00 o B S S e A D