The Nonpartisan Leader Newspaper, January 26, 1920, Page 4

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

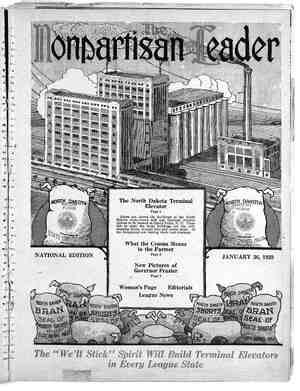

5 ¢ t . The North Dakota Terminal Elevator A Description of Its Construction and Operation and a Discussion of The author of this article is an engineer associated with the Charles L. Pillsbury company, engineers, of Minne- apolis and St. Paul. This firm is in no way connected with the Pillsbury Milling company, but makes a specialty of designing and constructing mills and elevators and was for this reason engaged by the North Dakota industrial com- mission to design the state-owned plant planned for Grand Forks. Mr. Lykken is a North Dakotan, a graduate of the University of North Dakota, and for this reason is es- pecially interested in the big industrial enterprise to be planted in his state. BY H. G. LYKKEN HE terminal elevator planned for the state of North Dakota and to be lo- cated at Grand Forks consists of a cleaning house having a handling capacity of 12 to 15 carloads per hour, and storage bins with a capacity of 1,600,000 bushels. A mill having a daily capacity of 3,000 barrels will be built and operated in con- nection with the elevator, utilizing the same power plant, thus effecting a large saving in overhead and power cost. The cleaning house (the high building shown in the center on this week’s cover) is 60 feet by 120 |, feet in ground plan, and is 190 feet high above the foundation mat. The construction is fireproof throughout, being rein- forced concrete, with brick and tile curtain walls and metal sash on all work floors. There are four work floors above the house bins and one below the bins. All cleaning machinery is located above the bins. This is a novelty in the terminals of the North- west, and greatly facili- tates the handling of the grain. There are six receiving pits on two lines of re- ceiving tracks. This area is all housed over and paved. The grain is un- loaded by power unload- ers into the scale hoppers located underneath the tracks. The grain is weighed before it is dumped on the conveyor belts, although the general practice is to elevate it to the scale hoppers at the top of the cleaning house before weighing. Every possibility of loss is thus eliminated, as the whole operation, including the dumping of the grain, is under the full control and observation of the weigh- master. . When weighed the grain is dropped on a convey- ing belt which takes it to a lofting leg. This brings it to one of several garners at the top of the house. From the garners the grain drops by gravity to the cleaning machinery or may be by-passed to any of the house bins or storage tanks. The general prac- tice will; however, be to clean the grain as it is re- ceived. GROWER WILL GET CREDIT FOR ALL VALUABLE DOCKAGE The grain from the receiving garners, which all have a carload capacity, flows to the receiving sepa- rators on the floor below. The cleaned grain drops down on a system of distributing-belts which takes it to its proper storage tank, or into a carload capacity house bin, when it is desired to preserve the identity of any one car of grain. If desired, the grain can be passed through a second cleaning, necessary in some cases. The screenings are run through a screening sepa- rator which segregates the flax, mustard, oats and wheat that may be tailed over, and other seeds,and refuse. These various items are weighed, credited to the shipper and then distributed to their respec- tive bins. When a carload of mustard, flax or any other seed has accumulated it can be recleaned and disposed of as a carload item. The house is provided with grain washers and dryers, so that any damp grain can be dried. In case the grain is smutty, musty or bin-burned, it can be run through the washer and dryer. The shipping tracks are on the opposite side of the house from the receiving side and between the e—s—o—a NORTHERN PACIFIC mill, producing 3,000 barrels of flour a day, the Benefits It Will Bring cleaning house and the storage line. This area is also housed over and paved. Twelve to 20 cars per hour can be loaded. ” The ground floor of the cleaning house is used for feeding, grinding, packing, storage and shipping. The screenings and . grains to be ground drop from the bins above directly into the grinders. Every facility is provided at this point for the preparation of the by-products of the eleyvator and economical handling of them. The mill (the tall building shown at the front of the cover picture) is 42 by 160 feet, eight stories and basement, with a 3,000-barrel daily, output. It consists of two 1,000-barrel spring wheat units and one 1,000-barrel macaroni unit. It is electrically driven throughout. The transmission is ball-bear- ing and the power consumption will not exceed one horsepower per four bushels, or 24 to 30 pounds of coal per barrel. Construction of the mill and other buildings are reinforced concrete throughout. On either side of the mill is a one-story and basement This map indicates the territory from which the state-owned terminal elevator at Grand Forks, N. D., will draw its wheat and the two routes offered for shipment to the markets of the world. While the state will take care of much of the crop the bulk of North Dakota wheat will be shipped from the elevator, taking advantage always of the best markets available. wing, 42 by 200 feet. Milling will be carried on in the upper stories of the main building, the sacked flour being distributed by gravity to the lower floor and basement for storage or shipment. - The storage tanks consist: of 32 circular concrete tanks, 30 feet in diameter and 90 feet high, with 21 interspace bins, provided with the latest facilities for rapidly handling the grain in and out of storage. They are shown behind the workhouse in the cover picture. . In the above brief sketch it will bé noted that from 10 to 15 cars of grain can be received, cleaned and reshipped or placed in storage per hour. This large capacity is effected by the most modern sys- tem of handling the grain, and the elimination of much rehandling and re-elevation found in the older MILL AND ELEVATOR FACTS Mill (first tall building on cover)— 42 by 160 feet, eight stories high, with basement. Capacity, 8,000 barrels per .day. Cleaning house (tall building in cen- ter of cover picture)—60 by 120 feet, 184 feet high. Contains latest clean- ing, washing, 'drying, etc., machinery, as described in this article. Storage bins—32 circular bins, 30 feet in diameter, and 21 interspace bins. Total capacity, 1,600,000 bushels. Power plant (at right of picture)— Develops 2,000 horsepower for joint use of elevator and mill. " Loading sheds and track facilities— Allow handling of 15 carloads per hour. £EXPORT SHIPMENTS 70 DULUTH, 297 MILES. \\ QOMESTIC 7RDF 70 | S LTINNEBPLOLLIS 3/0MLES houses. Facilities are provided for handling any grain which may be received. The following are some of the distinctive features offered the patrons: - 1. The grain is weighed in the track hopper, thus eliminating any possibility of accidental or inten- tional loss. 2. It is cleaned as received and the exact amounts of various grains and seeds in the dockage credited on the carload receipt. . 3. If the grain is damp it can be dried. ENTIRE PLANT OF LATEST STYLE OF CONSTRUCTION 4, If the grain is smutty, musty or bin-burned it can be washed and dried. 5. Any carload shipment can be stored and re- shipped. without mixing with other grains. 6. The by-products can be properly prepared and handled to the best advantage. . The plant as a whole is absolutely the latest and best in this class of construction. Nothing has been spared to make it so, as the best engi- neering talent experienc- ed in similar and larger plants both in this coun- try and Canada has co- operated in the design. It has many features not found in any other plant, as the request of the North Dakota industrial commission was for a - plant designed primarily to safeguard the interest of the shipper and the preparation of the grain for the best selling con- dition. Many questions have been raised in connection with the business phase of this proposition. 1s it not a new and untried experiment? Will it be of any benefit to the state? Will it be a safe financial venture for the state? Is the location within the state as desir- able as at an already established terminal market? The state-owned terminal is not a new thing. It has been advocated in North Dakota for over 20 years and was in reality started nearly 10 years ago by the amendment of the state constitution to provide for the building of one. The state of Louisiana owns and operates a 3,000,000-bushel terminal. In the state of Washington a large plant has for some time been in operation at Seattle. In Oregon one at Astoria is in operation, and one at Portland, having a capacity of 2,000,000 bushels, is now .being constructed, all three of which are, to the best information of the writer, financed by pub- lic funds—if not directly by the states themselves. In Canada several large terminals have been con- structed by the various provinces. TIn all cases the ventures have been successful and satisfactory. As to whether such a terminal operated as con- templated will be a benefit to the state—ean be best arrived at by a little comparison with present prac- tice in marketing grain and what will be done at this terminal. The bulk of North Dakota grain is shipped as it comes from the threshing machine, having from two to sometimes as high as 15 pounds of foreign grains, seeds and dirt per bushel. Often this dockage is good oats. It may contain from five to ten bushels per car of flax or mustard seed. The farmer and shipper pays freight on this to the terminal but receives nothing for it. In so-called dirty grain the value of the dockage runs up to a considerable percentage of the value of the car. (The new dockage law put through by the Non- partisan league has to some extent remedied this as far as North Dakota is concerned). . It is true that the farmer might clean his grain on the farm and save the dockage, but cleaningeon a small scale is too expensive.” The same is true of the cleaning in country elevators. On a small scale, it does not pay to install the proper machinery and separate and handle the screenings, as they should be handled. At this terminal each car will be clean-