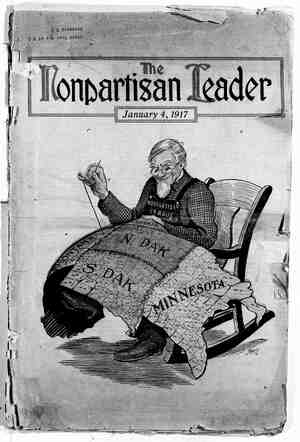

The Nonpartisan Leader Newspaper, January 4, 1917, Page 5

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

A Miller Recites Sonie eed” Wheat in His Best Flour. About Another Minnesota Mill { Uses One-third “F HE FARMERS who Yve in north- ern Becker county, Minnesota, and their wives do not believe the hard luck stories of the flour millers who have been saying they could - not make flour of the 40- to 50-pound grain that nature wished on the north- west this season. They have had nothing better than that, on the average, and the heaviest wheat raised there this year is said by those who have been buying ever since threshing time, and who ought to know, to be about 52 pounds. The average test weight per bushel of wheat produced in that region is 46- to 48-pound material when cleaned for the rolls. The elevators are taking a good deal of this but some of it they refuse to take, and the farmers have learned the same les- sons there that they did down in Otter- tail county, and are having their wheat ground for their own use, realizing from $1.50 per bushel up-for grain that is graded as “feed” and would have brought them under $1. The mill at Audubon, Becker county, Minnesota, has been busy ever since harvest time, grinding flour from the season’s rusted crop and pleasing the customers who had it ground. More than that, the mill is grinding, for its own merchant trade, a good deal of this same kind of wheat, about one-third of the mill stream being the light, shrunken kernels of the 1916 wheat, and two thirds old wheat. Everyone is pleased with the flour that is being made, and it has been warmly praised for superiority on some points, over the straight flour of other years. The housewives like it because it is “stronger,” will make a.lighter loaf of bread, and their husbands like it because it has a better flavor than the high-patent flour. The color question is the only ome in which it fails to measure up beside the best flours of ordinary years, and in many instances it is as good in color, although the general tendency is towards what the millers term “creaminess.” This creaminess again is due partly to the fact the wheat is not as dry as it might be, but is .unavoidable in the ‘Audubon mill, where there are not the best of facilities for drying the grain, and because the farmers have been keep- ing the mill so busy it had to put the wheat through as rapidly as possible. BIG MILLS USING EVEN BURNT GRAIN “If this wheat is as good as you say it is, why don’t the big mills use it in their regular brands of flour,” was asked of Joe F. Sippel, who has been running Frank LaCross’s mill at Audubon for - nearly three years. “They are using it,” replied Mr. Sippel. “That is, I am perfectly cer- tain that they are, although of course I couldn’t prove it. But from my own experience as a miller, and knowledge of the ‘way big flour mills operate, I know they are making flour out of this light weight wheat.” I have worked in large mills and have seen 50 per cent of Kansas wheat going into flour that was branded all No. 1 Northern. I have seen bin-burnt and moldy wheat going to the rolls and the mill never changed the brand on its sacks, which declared it was being made from the best selected No. 1 Northern. I saw 10,000 bushels of wheat that had been through an elevator fire, washed a couple of times and fed into the mill stream. As long as it didn’t exceed 10 per cent there was no danger of its giving a flavor to the flour, although of course that kind of wheat was dead— had no more life than so much chalk. It takes strong wheat like that of the 1916 crop to overcome this sort of thing in the flour, although the flour made from that burnt wheat was white and fine.” The title of that little bit of informa- tion might well be “Exposed from, the Inside.” Mr. Sippel has been a miller for years and announced the facts in a perfectly frank manner. He added that the mill he is now working in is using this same kind of wheat, although it has not gone .-below 48 pounds test weight per bushel in selecting grain for its commercial _grade of flour. RGIT. the mills are using this kind of ™ wheat to make flour, why do they attempt to conceal the fact—why do they not admit it?” Mr. Sippel was asked. He replied that the mills want to keep up their reputation, that they are afraid the knowledge that they are using this kind of wheat will hurt the sale of their flour, and so they keep up a vigorous denunciation of light test wheat to befog their customers (and also the farmers from whom they are buying it) and at the same time utilize the much maligned grain in their blends. Another fact, which Mr. Sippel did not mention, is that when the farmers become thoroughly awakened to the fact that the millers are using this “chicken feed” or “feed D” or —“feed C” wheat in flour for human con- sumption, they will no longer submit to the immense spread in price between it and the higher grades, but will insist that the flour makers divide up the profits with the wheat producers. The customers of the Audubon mill are” so well pleased with the flour that their scanty fields have yielded that they are coming for their second grindings and spreading the news among their neigh- bors. The fame of the once despised feed wheat is growing throughout this new region and other mills are setting them- selves to trying out this new thing—of Above—Frank LaCross’ flour mill at Audubon, Minnesota. ~ v Facts Some Other Things This is another practical flour mill that is disproving the loud assertions of the grain combine ini Minneapolis that the light-weight, rust stricken wheat of the 1916 crop is no good for making flour. - Below—A customer of the Auduhon mill, who has just come to get some of the flour made from featherweight wheat. Standing on the platform just beyond the team is Frank LaCross, owner of the mill, who has been in the business since 1876 and finds it profitable and satisfactory to customers to use one-third new light-weight wheat to two-thirds old wheat in making his standard grade of flour. S making flour from wheat that weighs less than 52 pounds test weight per measure bushel. After having learned the stories of some of them, another question was put to Mr. Sippel, and it was this: “If a 60-barrel mill like this one at Audubon can make good flour that pleases the American housewives who use it, why can’t the big mills of 500- to 2500-barrel capacity make even better flour?” BIG MILL FACILITIES GIVE BETTER RESULTS “They can,” he said. “With a long system mill better flour can be made from this kind of wheat than we are getting. We have three breaks and five reductions of the grain, and that is as far as we can carry it, but a mill with .a longer system, one that could reduce the stock still further, would ‘'get better results than we do. Another thing, in the big mills there are all the facilities nceessary for tempering, drying’or clean- ing the wheat. We are short of some of these things. If we had a dryer a good deal of this wheat would be dried instead of going to the rolls as it comes in, and this would improve its_ecolor. Wheat a little too damp makes flour inclined to be creamy in color. But this wheat has not the bad color defect of grayness, which makes_the dark loaves that housewives dislike. “One thing more—our customers demand that we get all the flour out of the grain possible, so we grind as close as we can. flour wolild be whiter. But it makes no ' wheat as the big mills. If-we were to:take out one: to two pounds less flour per bushel, the - difference to us, whether the wheat goes into flour or feed, and if they would pre- fer. to have an extra pound or two in flour than in the feed, we grind close enough to take out all the flour we can with our equipment. We get 15 cents a bushel and the farmers get all the flour, shorts and bran their wheat makes.” Here are several points from a miller who knows: First, the big millers are using the light test wheat in making their standard brands of flour; second they are kicking up the dust so the farmers and American housewives won’t get wise to it; third, the mills that own up to this terrible crime find satisfied customers; fourth, these little mills have not the facilities to make as good flour from this kind of Conclusion: the flour that the big mills are making from the farmers’ rust 'stricken, light-weight wheat, is even better flour than the excellent records this same kind of wheat has made in the North ‘Dakota Agricul- tural college mill, the commercial mill at Phelps, Ottertail county, Minn., and the commercial and grist mill at Audu- bon, Minn. EVERYBODY DOING IT; EVERYBODY’S SATISFIED As to how well the farmers like this much ridiculed flour, here are a few facts of record. Guy Ellerson of Audubon took 22 bushels and 10 pounds gross weight of wl‘xeat that tested 47 pounds per bushel cleaned, and got 568 pounds of “the best flour I've had yet,” 32 pounds of middle ings, 80 pounds of screenings, 430 pounds of bran, and 78 pounds of shorts. He liked it so well he started his neighbors hauling their “poor” wheat to the Audubon mill, and it worked like a “chain letter.” Everybody’s doing it now. John Dahlberg of Audubon took a load of 2132 bushels of wheat of 46 pounds test weight, got 600 pounds of flour, 69 pounds of middlings, 74 pounds of screen- ings, 330 bran and 174 of shorts. T. G. McNeal of Detroit, Minn., took a big load, 37 bushels, 35 pounds gross ‘weight, of wheat that graded as “feed® and was between 44 and 45 pounds test weight, and got 1015 pounds of‘flour, and all the trimmings in proportion.: He. took this first load-in* October, tried the flour for twp moniths. and a week ago was back with his second joad,and spreading the gospel of flour walus guaged by milling results instead of tH#e:; unreliable system of “fest weight per | bushel.” : John Wallace of Bucks Mills, Minn., brought in the lightest load of wheat that came to the mill this season—estimated (but riot weighed) at 42 pounds pe bushel. at Detroit, but the mill there had offered’ him 12 pounds of flour per bushel—that is, for every 60-pounds of wheat He ha and he refused to trade. It made &° little over 27 pounds of flour per bush and he took home a total of 579 pounda ; of fine white flour, 29 pounds of rmdqflé— ! ings, 155 pounds of screenings (an indica~ tion of its test weight) and 474 pounds of bran and shorts. S HOPES MOVE WILL SPREAD McHugh, Minn, Editor Nonpartisan Leader: Enclosed editorial from the St. Paul Daily News of December 21, “The Hay- seed in Politics.” This is but one of the many compli- mentary editorials and writeups in the Daily News during the last several months.: During the Fquity convention, column after column and cartoons boost~ ing the Equity and League were in each day. The Daily News has stood by the common people for years. Now that the Courier-News is to be the League’s daily paper, we can look for reliable information. What the League will accomplish in North Dakota during the next ‘few months, will be desired largely by the people over a large part of the country outside of North Dakota, el e TUMRT A W SV W W ommemawe ws ixogtiess nig It had been. refused at the mil "« \\ | ' Let us hope that several more states will } be organized and accomplish what North Dakota did November 7. For my part I was more interested in P the North Dakota election last November than I was in our own state election. Am mighty glad to hear that the Equity and League will work together from now on. The next move should be to work with all the labor organizations, and for the | interest of ALL. Cut out every middle- | man’s profit coming and going, is the, solution and the Equity and League are certainly starting right. , GEO. W. HARRIS. ~or