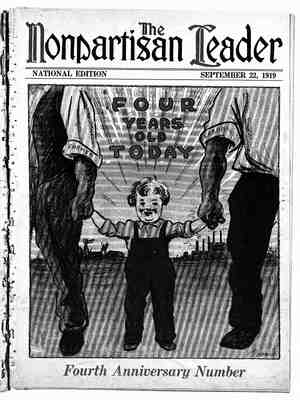

The Nonpartisan Leader Newspaper, September 22, 1919, Page 10

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

| ‘per cent of the egg crop is produced Preservation of Eggs by Cold Storage Interesting Facts on Modern System of Gathering Perishable Product in Spring and Holding It for Months of Scarcity ' The following article is taken from Bul- letin 7756 published by, the department of agriculture, Washington, D. C. This de- partment has prepared more than 25 bul- letins on producing, marketing and stor- ing eggs which would be of value to those especially interested in the subject. BY M. K. JENKINS (Government Bacteriologist.) -] HE preservation of eggs by means of cold renders one of the most impor- tant of the perish- able foods avail- able at all times. According to Holmes, about 50 during the months of March, April, May and June, and 86 per cent of the eggs held in storage are stored in March, April and May. During these cool months the eggs are the freshest and most desirable for storing. Ac- cording to a statement issued by the bureau of markets, April 15, 1918, - 478 warehouses, which report holdings of eggs in cold storage, are fairly well distributed over the United States. The March 11 (1918) summary re- port, issued by the bureau of markets, shows that a total of 6,595,850 30-dozen cases, valued at $70,- 487,212, were stored in 396 houses during the sea- son of 1917-18. These figures, although lower than the actual amounts, due, as mentioned in the re- ports, to the failure of a few houses to. forward statements of their holdings, give a fair approxi- mation of the extent and value of the business. The deliveries in appreciable quantities of eggs from cold storage .begin in August, continue in in- creasing amounts during the fall and early winter months, and gradually decrease from this period until March 1, when there are but few, or prac- tically no eggs left in storage in normal seasons. For example, during the season of 1916-17 57.7 per cent of the holdings were left in storage on No- vember 1, 34.2 per cent on December 1, 13.8 per cent on January 1, 2.1 per cent on February 1, and 0.1 per cent on March 1. The increase in consump- tion of cold storage eggs during the winter cor- responds to the marked decline in egg production during that time. Although a number of publications discuss the losses in eggs which follow the routine course of marketing without the intervention of cold storage, comparatively few data, showing the changes and losses in different grades of eggs handled accord- ing to commercial usages during various holding periods in cold storage, are available. This inves- tigation was made primarily to determine the ef- ficiency of the preservation of commercial eggs by cold storage. 2 The losses in commercial fresh eggs with clean, . sound shells were found to be negligible during a storage period of 11 months. In the investigation the bad eggs detected by candling and breaking did not amount to more than five eggs per case at any time during the storage period. The principal types of bad eggs found were green whites, crusted yolks, moldy eggs, mixed rots and white rots. The first two types mentioned are characteristic of washed eggs after storing. Unfortunately it is not possible to detect all' washed eggs by inspec- tion of the shell before storing. DIRTY EGGS SPOIL MORE QUICKLY THAN CLEAN If the shell of a fresh egg is dirty its liability to spoilage during holding in cold storage is markedly increased. A typical lot stored in April showed on monthly withdrawals from storage from Sep- tember to March, inclusive, from 12 to 30 bad eggs per case by candling and from 10.5 to 29 additional by breaking. " Among commercial dirty eggs are found eggs - soiled with feces, mud and blood, as well as stained eggs showing evidence of having been washed or having come in contact with the wet, muddy feet of hens or wet nests. 'Bacteria and molds can pene- trate wet shells, even though unbroken, and cause the egg to rot.~ Moldy eggs, green whites, crusted yolks, mixed rots, white rots and black rots are the principal varieties of bad eggs among dirty refrig- erator eggs. . 3 There are fat months and lean months in egg production, and if people wish to consume eggs during all the months, they must do what Joseph did in Egypt—store the product in the fat season. In the last 15 years private interests have made great developments in the cold storage methods of handling eggs for the lean months, but they have used the system to hold up the consumers, just as the Egyptian farm- ers were impoverished by Pharaoh in paying for the grain they had themselves raised in the seven good years. The Nonpartisan league farmers hold that the cold stor- age method should be made available to the people at cost. With plants for this purpose in the smaller centers near the farms, all kinds of perishable products could be stored and the community made independent of the food monopolizers. Many of the losses from shipping goods long distances, as in the case of eggs, would be saved. Communities could come very near to being self-supporting and free from the waste and profiteering of distant markets. real punch to get it. Our modern Pharaohs have a profitable business and they will'not part with any of it without a fight. It is generally known that eggs with damaged shells will not keep in storage. The most common form of deterioration of the cracked egg is through molding, which, in stocks stored in spring, becomes pronounced in September and October, and in- creases throughout the storage period. The bad eggs developing in cracked eggs stored in April and May varied, as found by candling and break- ing, from 44 per case in September to 144 per case in March. If the shells were dirty in addition to being cracked, the losses were greater, amounting in eggs stored in April and held until December to as high as 211 to the case as found by candling. These observations were made on damaged eggs” present in first-grade commercial packages through oversight or carelessness during the initial sorting of the eggs for storage. The losses found would have been higher had the observations been made on cases containing only cracked eggs, for the mold growing on one egg readily spreads to other broken eggs. : These studies emphasize the importance of select- ing only eggs with clean, sound shells for storing. The initial quality of the eggs influences to a large extent their preservation by cold storage. A typical cold storage room for eggs. In the upper right-hand corner are the brine pipes which fur- nish the low temperature required. This one room _ has a capacity of 4,000 cases, or 1,400,000 eggs. Sometimes the owner of the plant stores the eggs, or. the space may be rented by others for the ‘same?;_‘lpu_vrppse.f ' PAGE TEN e But we must organize with a is a foreign flavor absorbed by the eggs. Stale, weak and hatch-spot eggs, which are only too plentiful in eggs marketed in the summer, lose heavily after a few months holding in cold storage. Py i Most of the grading of eggs for storage is done in the producing sec- tions, although some ungraded cur- rent receipts reach the markets in the consuming centers, particularly from shippers located in the undeveloped poultry and egg sections of the country. HOW EGGS ARE CHOSEN FOR STORAGE The usual procedure is to sort the current receipts into various grades by clicking and inspecting the shells. From the case of current receipts the sorters take in each hand three eggs, which, by an inward movement of the index finger, they click together. A clear ring indicates whole shells; a deadened sound signifies the presence of cracked eggs. The latter are sort- ed into cases by themselves, as are also the small and dirty eggs. These eggs are marketed for im- mediate consumption, or are broken and frozen in cans to be used by bakers as needed. Undergrade eggs, consisting of those which are dirty, small, shrunken and heated, usually are mar- keted directly in the shell or used in the prepara- tion of frozen and dried products.- These grades of eggs are very seldom stored, except for short intervals, as the industry realizes that they do not: keep well in storage for long periods. It is fre- quently convenient for the management of egg- breaking plants to buy large quantities of seconds in the spring when eggs are plentiful and cheap, to store for one or two months, and to open when the supply of these eggs on the market is short and when otherwise the breaking room would be practically idle. This practice is warranted only for very short intervals. In short, for successful preservation in storage in the shell, eggs, like other perishable products, must initjally be in prime condition. During the commercial holding of eggs in cold storage the air space increases in size because of ~ the evaporation of moisture; the white becomes thinner and eventually loses its opalescence. After six or seven months the white usually develops a yellow tinge, which deepens with the length of the storage period. The clouded appearance of the white is especially noticeable when eggs are sep- arated in large quantities, as is done in a com- mercial egg-breaking room. The slightly yellow color does not destroy the beating quality of the Yhite nor the porcelain -white color of the result- ing froth, The yolk membrane weakens slowly, but, if the eggs are fresh on storing, most of them can be separated, even after storage for 11 months. The separation, however, is usually not as easy as in the earlier part of the storage period. If the physical condition of the egg is weakened through being stale, or heated, or both, separation is diffi- cult after being held in storage for only a few months. It has been found that under commercial con- ditions a characteristic unpléasant flavor, common- ly termed the “cold storage taste,” develops in eggs which have been held in cold storage for sev- . -eral months. It is especially noticeable when the eggs are soft boiled or poached. The flavor is not as marked in the white as in the yolk, which con- tains a large percentage of fat. It is' known that fats have an affinity for odors and flavors. The facts indicate that the “cold storage taste” is diie to’ the absorption of surrounding odors. When closed the storage room itself has some odor, as- have also the cases and excelsior, but the straw- board fillers and flats possess an odor meore nearly resembling that found in storage eggs. The fillers and flats become slightly damp in storage, due to the absorption of moisture evaporating from the eggs and the air of the room, and acquire a strong- er odor than when dry. ' Experiments show that when: €ggs are protected from air by immersion in a preserving liquid and held in cold storage, the typical “cold storage taste” does mot develop. This shows almost conclusively that the “storage taste” -