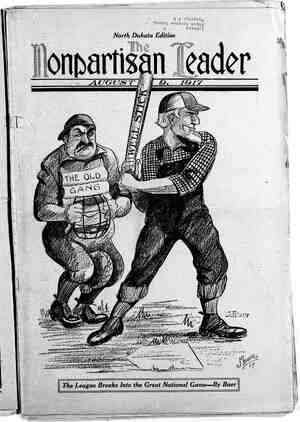

The Nonpartisan Leader Newspaper, August 9, 1917, Page 6

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

North Dakota is almost certain to be faced with a serious shortage of fuel this winter. To relieve this shortage Dean Babh- cock urges that preparations be made to use all the lignite possible. ‘‘The use of lignite is increasing as people learn more about how to use it,”” he says. ‘‘Nearly everyone can use it to supple- ment the supply of other coals, at least. Get it in small lumps, if possible, as it keeps better that way. Keep it in the basement. Dampness is beneficial to it. It will need to be fed more frequent- ly than other coals and will be found most serviceable in the milder weather, perhaps supplementing it with hard coal in the severe portion of the winter.”’ Dean Babeock is preparing a series of articles on the use of lignite as a measure to help relieve the coal shortage. of treasure, and then took me into the laboratory and showed me what is hid- den in those dun-colored lumps that they are digging out of the ground in the western part of the state. I repeat for him' in substance the story as he told it to me. “The North Dakota lignite as it is mined,” he said, “contains from a quarter to a third of water.~ When large lumps of the lignite are exposed to the air and the water evaporates the coal scales off until finally it be- comes a heap of dust and small frag- ments, Then, of course, it has little value for ordinary uses as a fuel. But that is not the only drawback to its use in the natural state. The coal can be dried out and then pressed together into cakes or briquets for use in the stove or furnace. These would burn better, than the lignite in the original lumps, but they have another great defect. When it is heated in the fire lignite immediately begins to give off light, inflammable gases in great quantity. These gases form so rapidly —are so volatile, as we say—that they force the coal apart into fragments and briguets made simply of the natural coal dried and pressed together will break up quickly in the fire and much of it will be lost through the grates. BRIQUETS HE MAKES ARE EXCELLENT FUEL “The process we have worked out for making a more valuable fuel out of the lignite is to_‘carbonize’ it. The carbon is the heart of the coal. Lignite when dry is about half fixed carbon, about 39 per cent volatile matter in the shape of oils and gases and the remainder ash. We bake the coal in a retort or oven such as is used for making gas from soft coal. In this way we drive off a part or all of the gas and oils. Then we take the substance that is left, the heart of the coal, and after mix- ing it with a small quantity of hot coal pitch we press it together in a hydrau- lic press into little cakes or briquets.” Dean Babcock exhibited some of the briquets. As made at the experimental plant in the size which Professor Bab- cock has found most practicable, they are about an inch and three quarters square by an-inch thick. The briquets are tough and hard. They can be smashed hard upon the floor and will not break. They have been tested in crushing machines and in special “abrasion cylinders” and they have been found more durable even than an- thracite coal. They have been left out in the sun and rain for six months without any noticeable damage. Though the day was the hottest of the, vear and of many other years— Dean Babcock had caused his helpers to build a fire in a little room in the basement used for coal testing pur- pose. There a big bed of briquets were glowing fiercely in a big self-feeding heater. The temperature of'the room, as noted by a recording thermometer, was 150 degrees IFahrenheit. It made the temperature of 109 degrees of the outside air seem mild and balmy. The briquets were burning” with slightly more flame than hard coal.. They light much more quickly than anthracite. Analysis shows them to contain just a trifle fewer “heat units” than anthracite. But they actually ac- complish more than anthracite in the stove because they burn up clean. There is no coal left in the ashes. Com- * bustion of the carbon is practically 100 per cent perfect. BETTER THAN ANTHRACITE IN MANY RESPECTS Dr. Babcock "took from the fire a white-hot glowing briquet which still retained its original shape. He held it under the cold water faucet and it emerged from a hissing cloud of steam as black’and hard as when it went into the fire. The briquets don’t break up at all in the fire. untill burned up clean. 2 They are in every respect a better fuel than any natural coal that can be bought anywhere. They have all the advantages of anthracite with none of its disadvantages. Dr. Babcock showed me the machin- ery by which the briquets are produced in the laboratory. There is the retort for baking out the gas, a grinding ma- chine for pulverizing the coal residue, a heating tank where the pitch binder is prepared, a’ mixing hopper where the coal and binder are mixed and finally a press consisting of two big rotdting cylinders with pockets in their circum- ferences in which the briquets are formed by pressure between -the two cylinders. TFrom this machine the briquets go to the open air to cool and dry, when they are complete. At Hebron, North Dakota, the state has an experimental plant in which the briquets are produced on a larger scale and under what are practically com- mercial conditions. This plant is capable of turning out two tons of briquets every hour and is automatic in all details, the material being They hold together” Flashlight photograph taken in North Dakota lignite mine. The photograph shows how the lignite occurs in horizontal layers or strata, generally about six feet through. handled- practically throughout the en- tire process by machinery. I asked Dean Babcock 'something about the cost of the process and the price at which this fuel can be turned out. “It would be impossible to tell at just what cost a large commercial plant could manufacture the briquets,” he said. “That would depend upon the use of the by-products and the location of the plant.” FIVE TO SIX DOLLARS FER TON FOR BRIQUETS Briquets made at the Hebron plant are being sold there at $7 a ton. “l am satisfied that they can be sold commercially for less than that and yvield a profit,” said Professor Bab- cock. “Between $5 and $6 a ton would probably be a profitable price.” The cost of the briquets is necessar- ily dependent upon the production of the by-products devcloped in - their manufacture., The chief of these prod- ucts is the gas which is distilled off the coal in the process of roasting it. This is certain to play a tremendous part in the development of North Da- kota, for reasons which will be made plain in a future article. The lignite industry in North Da- kota, comparatively neglected as it is, has yet made a mighty advance in the last ten years. The lignite deposits of the state are located for the most part west of a line drawn north and south through Bismarck. All of the coun- ties west’ of that line as well as Em- This photograph shows lighite briquets made at the experimental’ plant of the University of North Dakota’s school of “mines. In the briquet form the nioisture is eliminated from the lignite and the heating power is increased. - PAGE FIVE - mons and Burleigh to the east of it, _have lignite fields. There are more than a hundred mines in operation and they produced, it is“estimated, 650,000 tons in the last vear. This is roughly 2,000 tons a day, which amounts even now to a consid- erable industry. The workable veins, from 5 to 25 feet in thickness, range from 50 to 200 feet deep. \ STATE ITSELF OWNS MUCH LIGNITE LAND The process of making lignite into a highly valuable commercial fuel is no longer in the experimental stage, It has been proved out. The pioneering has been done. It only awaits develop- ment by those who have the courage and the initiative to take it up. « When it is taken up commercially the lignite briqueting industry will create other important industries, as will be made more plain in the succeeding article. One of the factors to be considered in speculating on the future develop- ment of the lignite industry tn the state is the fact that the state of North Da- kota owns a large proportion of the lignite deposits in the ~ twenty-four western counties of the state and that the United States government holds another large portion. Private capital has been reluctant to take“the necessary steps to develop the lignite coal industry along the lines where it will do most for the state of North Dakota. There are powerful in- terests which are not anxious to see the millions of coal trade with the East cut off. Here is a field promising for state enterprise, one which the state of North Dakota, through an able and far-seeing servant of the people, has itself pioneered and marked out. It would be but a ‘logical step for the state to continue on a larger scale and with its own mines and factories, the work which Dean Babcock has started. He has been working unselfishly for the people of the state, not for his own glory or riches. It would be his best reward to guarantee to the people the benefits of what he has given them. A NEW YORK VIEW ~ The newest third party of an agra- rian cast makes its debut in national politics with the election of John M. Baer to congress from North Dakota. The Nonpartisan league, which swept the state last fall like a whirlwind, was expected to have little trouble with its Republican rival. So solidly are the farmers, Democratic and Republican, behind the League that the old party lines count for little; it was an almost complete obliteration of them last fall which gave Frazier the governorship by a plurality of 67,000 in a total vote of 110,000. The statement that Baer represent Socialist principles is mis- leading except in So far as we may regard the Nonpartisan league, with its demands for state-owned elevators, terminal markets, slaughter houses, and so on, as tinged with socialism. Last fall the Socialist candidate for con- gress insthis district received only 622 votes in a total of nearly 35,000. Baer will represent the point of view of the Northwestern farmer, which is con- servative in as many ways as it is radical. — NEW YORK EVENING POST. -