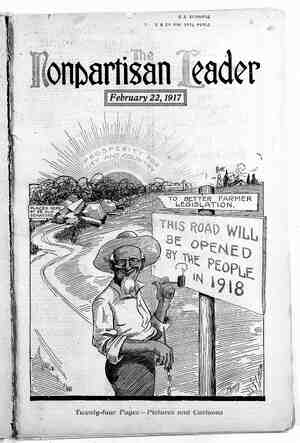

The Nonpartisan Leader Newspaper, February 22, 1917, Page 5

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

=% RS ST SRS S SR TR L A State Plant That Pays Big North Dakota Twine Industry Would Make Profit Even if Regular Wages Were Paid Convict Laborers By Ralph Harmon N THE 16 years of its operation, the binder twine plant at the North Dakota state penitentiary, a very small plant of its kind, has pro- duced met profits above its cost of operation and first cost of construc- tion amounting to $212,701. This in- cludes the profits of last year, up to the close of the operating season, September, 1916. It has paid its own way besides paying bonds, certificates of indebted- ness and interest amounting to $273,- 028, while the state today has a plant, and material for the 1917 manufactur- ing season invoiced at $400,000. The actual net operating profits shown by the warden's annual reports and by an expert examination of the books for the period up to 1908 amounted to approximately half a million dollars for the 16 years, or using the figures as nearly as . the imperfect accounting system of the early years yields them, $495,728. In recent years a more ac- curate system of bookkeeping shows the really handsome profits this state- owned industry is bringing to the citi- zens of North Dakota, besides the mil- lions in indirect benefit by way of low- ering twine prices. ’ The twine plant stands a bright ex- ample of a state-owned and operated industry, the only one in North Dakota worthy of the name of an industry, although there is a very profitable brick plant run also in connection with the penitentiary. The facts about this plant are all on the side of state owner- ship and operation. The people of the Northwest need state-owned and operated elevators in which to store the wheat that is bound by state- manufactured twine, and mills in which to grind that wheat, just as badly as they need the twine. PROFIT EVERY YEAR, THE FIGURES SHOW The first year the twine plant was in operation, 1900, it suffered a loss of $11,643.99. But for every year after 1900 up to 1908 it made a profit rang- ing from $14,000 to $47,000, and a total for the eight years of $225,892.66. For every subsequent year, its profits have not run lower than $22,000, and have gone as high as $69,000, except the year 1910, when a crop failure brought cancellation of many twine contracts and the material had to be carried over to next season. The total operating profits, then, for the entire period of its operation have been $495,728. Out of this had to come some heavy charges for starting the plant and wn immense interest item. The plant was authorized in the legis- lative session of 1889. The finance plan included the imme- diate issuance of $150,000 of certifi- cates of indebtedness to bear 6 per cent interest, and an issue soon after- ward of bonds to take up these certi- ficates and their interest. As a mat- ter of fact the plant cost more than was expected and $163,930 in certifi- cates were issued, but these were all retired later by bond issues or by di- rect profits from the twine plant. In 1901 and 1902 the bonds were issued. Authority was given to issue $210,000 in bonds, but only $169,000 were ever - actually negotiated, and the remaining $41,000 were destroyed (all except $20,000 which disappeared and have never been found). This bond issue wiped out the certificates of indebted- ness debt. A = The first bond series was to run for 10 years, maturing in 1911, and the second for 20 years, maturing in 1921, As a matter of fact, the plant paid so well, its product was so good and in such eager demand by farmers and by dealers, that it realized enough to re- tire all its bonds in 1914, thus liquidat- ing the debt seven years before it was due. The 1911 issue which was au- thorized at $105,000 (one-half of the total authorized amount) only came to $94,000, and these were all taken up May 9, 1911, a few days before they were due. Of the second $105,000 which had been authorized, only $75,- 000. was ever issued, and .these were were taken up January 10, 1914, out of the earnings of the twine plant. PLANT PAYS WAGES TO THE CONVICTS * But the plant had to pay a heavy burden of interest, all of which came out of its profits. In 1907 the plant had so well proven its financial strength that a lump sum of $126,307 was transferred from the credit ac- On top is a view of the entire lower floor of the twine plant where the sisal and manila is worked up from the bales of raw material into the long strands of fiber seen in the foreground of the picture. Starting at the other end of the long room, where it is threshed through the breakers into the first long skeins of fiber, it progresses through many breakers until it reaches the end in the foreground of this picture and goes through the finishers. The skeins seen here are fed through the finishers into tall cans, which are sent upstairs to the spinning room. Breakers and finishers are merely end- less belts armed with sharp spikes, which pull through the fiber like a . comb, the fiber being retarded by going through rollers that work like a clothes wringer, The rope on the pulley seen in the foreground is the finished end of a rope coming off the rope machine. The middle picture shows the outside of some of the buildings. The long building with windows is the twine plant: Grouped near it are the sisal and twine warehouses. track that runs between. To the right is the carpenter shop. Some freight cars may be seen on the In the bottom picture cans of the finished fiber are seen here being fed into the spinners. The combing process is still further carried on, and the few strands that reach the other side of the machine are whirled into the binder twine use.d on the farms and rolled up on spools, from which it is later unwound into the 10-pound balls, in which shape it is purchased. of the penitentiary under the supervision of superintendents and and warehouses connected with it. count of the twine plant to the sink- ing fund account and the bond interest account of the state. This was to re- imburse the state for a portion of the running expenses, which had previous- ly been advanced from the general fund before the proceeds of the bond issue were available and for interest. The interest on the certificates of in- debtedness, which were the emergency funds to get the plant started, amount- ed in all to $36,681. The interest on the bonds from the time the first ones were issued until the last ones were retired, amounted to $67,347, which, added to the other interest, makes a total interest charge of $104,028. In ‘the earlier years of its operation the operating cost of the twine plant does not include wages for the con- victs who do the work, although it includes salaries of their overseers. During the last two years, however, wages have been paid, although small, the inmates’ item for 1915 being $13,- 911, and for 1916, $10,823. But even paying wages to the inmates, the plant earned a net profit in 1915 of $40,542, and in 1916 of $33.075. ¥t has been urged against the splendid showing of profits made by the twine plant that this ‘'wage item is not large enough, and that the twine plant is not a profitable industry. A Is this so? The convicts who do the work are costing the state something, and it is quite likely they are costing more than the wages of a good com- petent workman. The plant is not be- ing run on as economical a basis as a modern industrial plant should be, for it is still using belt driven steam ma- FIVE The work in both departments is done by inmates guards. From 70 to 85 men are employed in the plant chinery of 15 years ago, instead of electric dynamo-driven machinery, and much of the work is being done by hand that would be etonomically and more efficiently done by a plant built under the conditions of today for com- mercial purposes. WOULD WORK BETTER IF BY REGULAR LABOR Another item that should be borne in mind is that the. inmates are not as efficient as outside workmen. For instance, if the men who run the plant were regular paid laborers they would do a great deal more work and earn much higher profits than the present inmates, which would go as an offset to the present low cost of zheir labor.