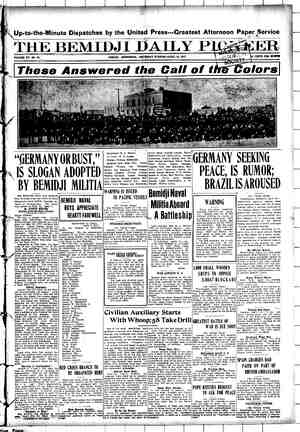

Bemidji Daily Pioneer Newspaper, April 12, 1917, Page 3

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

| THURSDAY, APRIL 12, 1017. flllalaic.. &« ARMORED VESSELS ‘/ How the Great Steel Plates That ; Protect Them Are Made. i A SEVERE TEST OF SKILL. The Various Processes That Produce the Conflicting Properties Necessary In These Modern Projectile Resisting Warship Jackets. Only armored warships could live in & naval battle with modern big gun projectiles in use, and hence the mak- ing of armor plate has become a sclence. The manufacture of armor plate has developed considerably in re- cent years, and in no branch of the steel industry is there greater oppor- tunity for engineering and mechanical skill, coupled with metallurgical knowl- edge, than in the operations of forging and rolling, followed by the exact heat treatment essential to produce the al- most conflicting properties necessary / in modern armor. ‘®he plate must be hard, glass hard, resist penetration by heavy projec- es moving at tremendous velocities, ~yet tough and fibrous enough to take | up the momentum without cracking or Mechanically, then, the plate must have an extremely hard surface and a fibrous backing. These requirements were attained in part by the old compound armor. Molten steel (was poured on to a wrought iron plate and cooled. The slab was then re- {heated, forged and rolled to the re- e hmlnll dimensions. If the operations y '/were successfully carried out the line of demarcation was scarcely visible. Recently a modification of this proc- ess was infroduced to cheapen and render less tedious the production of armor. A layer of bard steel was poured into a cooled mold, the under- side quickly setting. On the still fluid or pasty surface a thick layer of soft was poured. By careful manipu- lation the union of the surfaces was imost complete, and 1t was impossi- . ble to detect the break in composition on viewing the fractured section. This ) method of manufacture was undoubt- edly an improvement on the old com- pound method. The increasing size, velocity and hardness of modern armor plercing projectiles bave necessitated the intro- duction of ‘the modern armor. The process of manufacture essentially consists in case hardening to a depth of about two Inches the surface of a homogeneous tough nickel chrome /' steel. Special alr or self hardening nickel and more complex steels are p ed for lighter armor, gun shields .. and: cast armored structures. The steel Is made in Siemens fur- naces and carefully cast into ingots up to eighty tons in weight. These in- gots are then slabbed under powerful hydraulic presses (18,000 tons) or roll- ed. direct to the required dimensions, depending on the power of the mills and appliances. During the rolling operation, which lasts about an hour, the slab is reversed and inverted to at- tain uniformity of working, and scale 18 removed by wood fagots and wa- ter jets. After rolling the plate is gfually quenched. The next operation is that of case- bhardening, and in this two plates are put face to face, separated by a layer of the carburizing reagent if it be solid, or if gaseous hydrocarbons be used the plates are slightly separated, to allow free passage for the harden- ing gases, by bricks arranged in rows, The plates are maintained at redness in a car furnace for three weeks and withdrawn after the hardening carbon bas penetrated to the required depth. The plates are thus carburized and so made capable of being hardened, but they are not yet actually hard. At this stage all holes are drilled and plugged, and any bending or machining neces- sary is carried out. From this point onward the treat- ments differ. Some makers insist on heating and quenching in oil or water to remove any coarse structure that may have been formed during the long annealing while carburizing. The next essential operation is that of ardening, and this is usually car- out in one of two ways. REither the plate is uniformly heated to the fhndeulnl temperature and quenched by a series of water jets playing on the ‘upper surface with sufficient force to prevent the formation of steam or by a process known as “differential quenching,” by which the carburized surface is heated to a temperature from which it will harden and the |. under side kept well below, so attaining a gradual fall in temperature from the top to the bottom. The whole plate is then immersed in water, the hotter sur- face alone belng hardened, while the bark is toughened. Further mechanical operations can be carried out only by grinding or cutting with oxyacetylene, the plate has now undergone the freatment conferring maximum hard- ness. In resume, it will be noted that there are three distinct operations in modern methods of manufacture—the mechani- cal working of the plate to the required dimensifons, the carburization of the surface, quenching the carburized surface to harden it. These operations call for exact manipulation, super- vision and control, for the skill of the engineer and metallurgist may be put severest tests, not of the labora- or the testing machine, but out in “gray mists,” when faflure of a unit may imperil the safety and co- "4 besion of the whole.—Chambers’ Jour- 4 nal One that confounds good and evil is an enemy to good.—Burke. - SAVE THE TREES. The White Pine Blister Rust and a Warning and an Appeal. The American Forestry association has issued a warning and appeal for co-operation in fighting the disease known as the white pine blister rust that threatens the destruction of all the white pine and ofher five leaved pine trees in the United States. This disease has already appeared in Maine, New Hampshire, Vermont, Massachusetts, Connecticut, Rhode Is- land, New York, New Jersey, Pennsyl- vania, Wisconsin, Minnesota and in Quebec and Ontario. There is no known cure for it, It kills the white pines infected, and it spreads steadily. The spores or seeds are blown from diseased pines to cur- rant and gooseberry bushes. They germinate on the leaves of these bushes. The leaves then produce mil- lions of spores or seeds of the disease, which are blown by the wind from the bushics to the pines, and these, even There’s THE BEMIDJI DAILY PIONEER those several miles distant from the nearest bushes, are infected, become j diseased and die. The white pines in New England are worth $75,000,000, in the lakc states $96,000,000, in western states $69,000,~ 000 and in the national forests $30,- 000,000, or a total of $261,000,000. Unless the ravages of the white pine blister rust are stopped these pines will be destroyed. The American Forestry association urges people in all the regions® where the disease has Deen discovered to de- stroy at once all currant and goose- berry bushes, diseased pines and oth- ers exposed to infection. This will help stop the spread of the discase. The great forests of dead and dying chestnut in Pennsylvania, New Jersey. New York, Connecticut and Massachu- setts stand today mute but convincing witnesses to the fact that such dis- eases must be checked, if at. all, in their early stages. The pine growth of this country is far more valuable than the chestnut more fo this cigarette than taste A heap more. Most any cigarette can please the taste— somebody’s taste. Bu.t this Chesterfield Cigarette, in addition to pleasing the taste, gives you a new kind of enjoyment in cigarette smoking— _Chesterfields let you know you are smoking— they “SATISFY ! And yet, they’re mild/ It’s all due to the blend—the blend and the quality of the tobaccos. For we tell you that such costly, high-quality Imported and Domestic tobaccos have never before been put together in any cigarétte at anywhere near the price. And the blend can’t be copied. Words can only zell you these things—it takes the cigarette” itself to prove them. You’ll be glad you tried Chesterfields. ' Lggett e Mpors Toboooo O Do it today. Attractive tins of 100 Chesterfields sent, of 50 cents, if your dealer cannot supply 20£:10¢ ever was, and the damage the Dlister ru_ut may do is accordingly greater than the injury that has been or can be wrought by the chestnut blight. . But experience’ proves that the rav- ages of the blister rust can be, if taken in season, stopped much easier than the chestnut blight. In a number of places where started it has been near- ly or entirely eradicated. May the pine forests of America be saved and not neglected as the chestnut until it is too late!—Tree Talk. e i NOTICE In the matter of the Northern Min- nesota Dairy Farm Land Company. NOTICE IS HEREBY GIVEN that ‘William W. Congaon is not the agent for said Company and is not auth- orized to sell land for said Company or to receive money upon its account. NORTHERN MINNESOTA DAIRY FARM LAND COMPANY, By F. W. HALL, (Seal) Secretary. 12-412 Drepald; on’ reseipt you,” Addresas Liggett & Myers Tobacce Co., 212 Fifth Ave.,New York City. Chesterfield CIGARETTES of IMPORTED and DOMESTIC fobaccas — Blended y SatistyI-and yet they’ré Mild e These Are “Good - Sevice” Advertisers Offering you their “‘goud-service” and spending money to tell this commun- ity about themselves. Why not call them up? R R R R R R e R R R R R R R R R R R R « KOORS BROTHERS CO. %« Bakers and Confectioners & Manufacturers and Jobbers & Ice Cream, Bakery Goods, & Confectionery, Cigarsand x Fountain Goods % 316 Minn. Ave. Phone 125 EE KRR KKXX XX EREEERKEK KX X & MUSICAL INSTRUMENTS x Wholesale and Retail %« Pianos, Organs and Sewing x Machines 4« 117 Third St. * Phone §73-W x J. BISIAR, Manager Bemidji R R R R R e R S R R R e R R R R R +¥%x DRUGS AND JEWELRY <&¥ %% Wholesalers and Retallers &« +¥ Service and satisfaction. Mall & #% Orders given that same ser- ¥ %% vice you get in person. K *x BARKER'S K %% Third St. Bemidji, Minn. & & EE R XX R XXX KKK KR I EEE R EEEEREEERESS K K & L 34 K PHOTOGRAPHER K K Photos Pay and Night K *& N. L. HAKKERUP K K K *x *x GENERAL MERCHANDISE * Groceries, Dry Goods, 8hoes, € Flour, Feed, etc. The careful buyers buy here. W. G. SCHROEDER Bemidji - Phoue 66 I EEE R R R R R RN EEEREEEEEEEEEX DEAN LAND CO. Land, Loans, Insurance and City Property Troppman Bloek Bemidji (AR E R R EEERE R ER R Knapp's Shoe Store We have just received a lot of new shoes from the Utz & Dun factory. Look them over if you are in- terested in the new spring shoes for we have some that are extremely stylish and nifty. Black Kid Lace Boot Black kid, high top lace boot with leather Louis heels. Something dif- terent in @ black shoe. Sizes 234-8, widths B-D. Also same thing in a soft, dull calf high top boot. Plum Colored Boot A new plum colored boot just ar- rived. Either in a button with a flexible hand turned sole or a ldce. Soft Black Kid Silver Gray Kid Here is one of the most popular boots out for spring in the rich Sil- ver Gray Kid, cut with the square throat front and long vamp, giving the preferred style of slenderness to the foot. Covered Louis heels. A-C widths. A new boot just received by ex- press this morning in a soft black kid lace with a white kid A new style of shoe and we have all sizes from 2% to 7. Widths A to D. inlay. Just like above cut with a dark gray bottom and a white kid top. We have this style of shoes in several different {eathers. (1)—Soft black kid high top with a medium high curved.heel. All sizes 2% to 8. Widths B to E. (2)—A new fawn colored buch shoe that is in much gdemand this spring. Comes in a high leather Louis heel. Widths A to D. 3)—A medium shade of brown wi a snow white top. Very dressy. (4)—Same style in an all-white kid lace boot, except with a stitched tip and foxing. curved heels. White soled and (65)—High top lace boot in a white buck. heels. Plain toe and curved (6)—Soft black kid lace boot with a white kid top. (7)—Black kid lace, long vamp and high leather Louis heels with a black cloth top. A new one. —_— e A more conservative style in a black kid but either medium heel or high straight heel, with or without tip. [ TXYYYYY) Q A FULL LINE OF EDUCATORS FOR THE WHOLE FAMILY DO YOUR FEET HURT? Remember we carry & full line of foot appliances—arch supports, etc., and we can fit them to your feet, too. Knapp’s Shoe Store