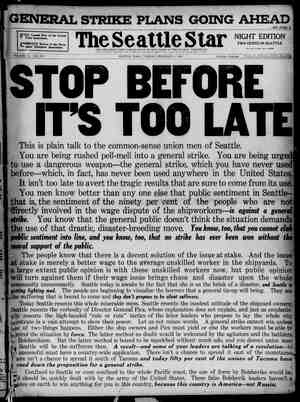

The Seattle Star Newspaper, February 4, 1919, Page 9

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

<3 | | | | i i eee Shipworkers’ Strike A Colossal Business Mistake The future of the shipbuilding industry lies with the men and the management. It is as much the problem of the one side as of the other. Increased output and lower costs can be secured by more intelligent direction and effort without a sacrifice to either side. But it can be done only by sympathetic and intelligent co-operation between the shipwork- ers and the yard owners; never by strike and strife. The strike is not only a breach of an agree- ment with the government, but, with the future of the industry hanging in the balance, it is a colossal business mistake, Congress authorized the President of the United States to spend three billion five hun- dred million dollars ($3,500,000,000.00) for the construction of ships and the President selected the Emergency Fleet Corporation as his agent to carry out this program. The German sub- marine was at that time sinking vessels from four to five times as fast as English and Amer- ican yards were producing them. It was America’s job to beat the submarine. Old shipyards were extended and new yards were built on both the Atlantic and Pacific Coasts. Contracts were placed for wood ships, com- posite ships, concrete ships and steel ships—for any ship that would float, propel itself and serve any kind of a useful purpose — because we were building a fleet for emergency. Wages were increased. Overtime and Sun- day work were ordered. Carloads of necessary material were sent by express. Three hundred thousand men were added to the fifty thousand shipworkers, and the government bore the ex- pense of transporting them and training them. | The government paid these beginners high wages while they were acquiring skill and ex- perience. For the nation needed ships and was willing to pay the price. The yards of the Pacific Coast and the Great Lakes responded nobly, for they had been longer in the game and had a larger number of experienced ship workers to draw from. Even the new yards created since the war was de- clared began deliveries. Then the armistice was declared and the building situation was changed over night. The nation began figuring the cost. And the Emergency Fleet Corporation was asked, “If you were building a lot of ships for Statement No. 2. an emergency, why don’t you quit now that the emergency is over? “Ships are costing the government from two and a half to three times what they cost three years ago, and fifty per cent. more than they, can be bought in England at the present time. So quit building till the costs go down to where we can compete.” The Emergency Fleet Corporation there- upon took account of stock. It found that it was building more wood ships than it could use or sell, and so it canceled those that had not been begun. It was found that a merchant marine was something more than an aggregation of ships. It had to be a well balanced fleet that provided a certain proportion of fast passenger ships, of , slower going passenger and cargo carriers, and of many ships built especially for certain lines of trade. And upon review of the numbers and types of vessels building under the emergency pro- gram, the Emergency Fleet Corporation de- cided to suspend work on a portion of it, so in case congress decided to permit us to spend the money authorized, it could substitute more de- sirable and necessary types of ships for those suspended. It is impossible to build a perfect “ready to use” merchant marine. Part of it at least must be built to suit the needs of business that will develop through the effort and enterprise of the future. It is necessary, therefore, to proceed mere slowly than heretofore in the completion of the present program. Over- time and Sunday work and other expenses due to speed have therefore been cut out. And we are calling on the managements and the ship- workers to co-operate in such a way as to make high wages and low labor cost possible in the shipyards as it has been made possible in the automobilé industry. Let me cite these examples of how high wages and re- duced output per man have increased the labor costs of ves- sels. One of the best producing yards on the Pacific Coast shows that the average output per man is seventy per cént. of that of ten years ago, and the average rate of pay seventy per cent. higher. This means a labor cost two and four- tenths times greater than two years ago. Three Atlantic Coast yards show labor cost from two and a half to three times higher than two years ago. We can look for more output per man as the new men in the yard grow in experience, but in the meantime the future of the industry is in the balance. Foreign orders cannot be secured until costs go down and even the government cannot continue shipbuilding indefinitely if every ship shows a heavy loss. I am presenting the facts as they are before the United States Shipping Board and the Emergency Fleet Corpora- tion, and my advice to the men is: Go back to work and get together with the owners to see what can be done to put the shipyards in shape to compete for the world’s business in shipbuilding. (SIGNED) CHARLES PIEZ Director General United States Shipping Board Emergency Fleet Corporation.