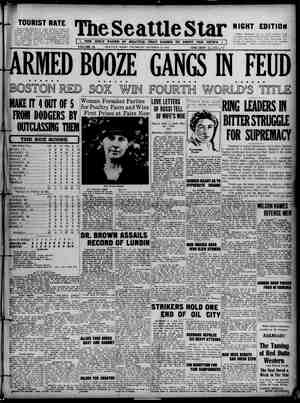

The Seattle Star Newspaper, October 12, 1916, Page 7

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

STAR—THURSDAY, OCT. 12, 1916. PAGE 7 To the Mayor, the City Engineer The City Council and the Taxpayers of Seattle - Concerning the Cedar River Pipe Lines WE: the undersigned, representing important industries of Seattle and the State, present herewith this petition endorsed by the New Chamber of Commerce of Seattle and the - Manufacturers’ Association of Seattle: Being informed that it is the intention of the city authorities to specify all-steel pipe for Cedar River Pipe Line No. 3, we respectfully and formally request that, before final specifications are drawn for this important work, that there should be appointed a proper board of investigation to inquire fully into the advantages of wood-stave, steel-banded pipe as compared with all-steel pipe. HIS board of investigation, we suggest, shall be composed of competent engineers and business men, and should fully investigate: First. The comparative reliability of various types of pipe from an engineering standpoint Second. The relative cost, including depreciation, of various types of conduit designed to give the same service. Third. This inquiry should fully take into account that wood stave steel banded pipe can be furnished en- tirely by home industries, including its labor, lumber, steel bands and creosoting, whereas the specifications of steel pipe involves the spending of a large percentage of its cost in distant markets We contend that there are substantial grounds for such an inquiry, and submit as a partial argument the following exhibits which distinctly show that wood stave pipe with steel bands for the Cedar River Pipe Line is true engineering, true economy and helpful home-industries boosting Discrimination Against Local Products Will Cost Taxpayers Millions The immediate proposition before the city, and which concerns vour petitioners, is embodied in the recent report of City Engineer Dimock and Superintendent Youngs, recommending the investment of about $1,250. 000 in all-steel pipe, whereas the use of wood stave and steel banded pipe would mean an investment « proximately $500,000. Their report is a final approval of all-steel pipe and contemplates the ultimate in vestment of over $5,000,000 in this type of aqueducts. This is a recommendation of tremendous import whether we consider it in whole or in part; and is so vital, so huge, so important that it positively demands a searching inquiry from every point of view and one that will be impartial and satisfying to every interest concerned. Interesting Facts for the Taxpayer There are few differences of opinion between competent civil engineers as to the relative merits of various materials for aqueducts. Concrete, steel, wood—each has its peculiar qualities. Engineers generally are well informed as to causes when these materials fail. There have been fewer disastrous failures of wood than of any other type of conduit. Los Angeles, California; Portland, Oregon, and Montreal, Canada, have recently experienced costly failures of other types of pipe. Yet the values and merits of steel and concrete are understood and their failures do not utterly con- demn them. Our present Cedar River Pipe Lines are wood stave and have never been directly chargeable with a water shortage. Considering the only two serious interruptions of service in 14 years’ use the first was chargeable to the washing out of a bridge, the second to the emptying of the pipe liné with the vent pipe frozen, causing collapse. Either of these interruptions to service would have been much more serious and costly had any other sind of pipe been in use. . Our Officials’ Own Figures Favor Wood Stave Pipe In the report entitled “The Seattle Municipal Water Plant,” issued in 1914 by the City Water Dept., pages 208 and 209, will be found a comparative cost of maintaining both steel riveted and wood stave pressure pipe lines based on actual figures relative to the Cedar River Water Supply Line No. 1. In this statement by the Chief Clerk and Auditor is demonstrated; on the assumption that steel pipe has a life of 45 years and also assuming that the staves of wood pipe are renewed every fifteen years, then, with the money at 5 per cent, which is the rate of interest paid on the original bond issue, at the expiration of 45 years (the assumed life of steel pipe) the city will have been able to completely renew the staves of the wood pipe three times and show a saving in cost in favor of wood pipe of $1,413,756.35. Recommendation by The Manufacturers’ Association River Pipe Lines. this important business, West Coast Lumbermen's Assn., Beattie, Wash, From @ review of the facts presented in the matter of the ma- to be used in the greater part of the extensive Cedar river pipe a thoro O iin t is unquestionably the merits of wood pipe materials be ommend to the elt in contract be signed and no final decision this work until such thoro investigation ts fin Yours respectfully, MANUFACTURERS’ ASSOCIATION Clancey M. Lewis, Secretar: COCO COCO OOOOOOOOOOOOOOOOOOOOOOOOOC® we shall rec- tment that no THORPE BABCOQCK, Secy. Above are presented highly important matters of local interest, of municipal economy and of practical engineering, all favoring the use of stave pipe for the construction of the Cedar We therefore petition as above set forth, that a full and proper investigation be made, and suggest to that end that public bodies appoint suitable committees to act jointly or severally in You are invited to address all communications to the WEST COAST LUMBERMEN’S ASS’N Tenth Floor White Building, Seattle. You will be interested in the Wood Stave Pipe Exhibit, Corner 4th and University, on the Metropolitan Bldg. Company's lawn, outside the Fisheries Building. Dealing with these same figures in another manner, the estimated cost of 22% miles of 14-inch steel pipe in place, including excavating and backfilling, is placed at $1,034,262.00. The actual cost of the wooden pipe installed, including excavating and backfilling, was $322,952.21. This was an initial saving in favor of wood pipe of $711,309.79. This wood pipe has served for 14 years, If we should put the $711,309.79 out at 5 per cent interest, compounded annually, it would earn in interest in the 14 years—$697,083.59. This would entirely replace the wood pipe—excavating, backfilling, bands, shoes and all at its entire original cost, which included grub- bing, trestling, making of fills and a number of other items that will never have to be done again, and leave $374,131.38 of interest to be applied to other uses, and still have the principal intact. The above figures refer to wood stave pipe having untreated staves. Treated Wood Stave Pipe Will Last Like Steel We quote from the report of the late Benzette Williams, a prominent hydraulic engineer who was engaged by the city to investigate the possibilities of a water supply from Cedar River. This report, submitted by him in February, 1890, is printed in the book referred to above beginning on page 42 and is as follows: “It is proposed to coat the outer surface of the staves and the iron bands, by dipping them in a kettle of hot asphaltum before they go into the work; and again, before the pipe is finally covered up in the trench, the outer surface of the bands and staves are to have another coat applied with a brush. The effect of this will be to make an impervious, unbroken coating, which will exclude the air and prevent evaporation of the moisture which penetrates the pores of the wood from the inside, and thus preserve the surface of the staves from decay, without regard to the character of the ground in which the pipe may be laid. The inner portion of the staves cannot decay, under any conditions, while the pipe is in use.” It is quite evident now that if Mr. Williams’ recommendation had been followed, pipe line No. 1 would today be in first-class condition An entire pipe line could now be built of wood staves, thoroughly creo- soted, which would unquestionably give a service as lasting as steel and at a saving of from forty to sixty per cent. Wood Stave Pipe Is the Big State Industry The Pacific Coast has an industry in pipe manufacturing which consumes about 40,000,000 feet of lumber annually, and the scientific improvements of late years in the manufacture of staves demand the earnest investigation and notice of City officials. Most of the causes of decay in wood staves have been eliminated by modern methods and the creosote treatment of staves gives a material of the highest class, and to repeat, the equal if not the superior of steel, in the opinion of reputable engineers. Seattle's Official Repudiation of Wood Stave Pipe Means the Killing of This Important Local Industry. In the matter of labor, if wood stave pipe were used a very large percentage of its cost would be for local labor, but with steel pipe the local labor item would be quite small. Making of Steel Bands for Wood Pipe Another Important Local Industry Wood stave pipe is encircled with steel bands and the making of steel bands and bars is becoming one of the most infportant of our local industries. This steel could therefore be manufactured locally. x] Rccethinandiiten by The New Chamber of Commerce Wert Coast Lumbermen’s Assn. Seattle, Wash. Gentlemen: From a review of the facts presented the matter of mate: to be used In the greater part of the extens¥e Cedar river pipe 1 it 1s unquestionably {mportant that a thoro investigation of t merits of Washington materials suitable for the above pipe lines be Made before the contract Is let, and we shall recommend to the city counct! and city engineering department that no contract be algn and no final decision made as to material for this work until such thoro Investigation Is finished, Yours very truly, « (Signed) R. HH. MATTISON, Bureau Secretary. J. H. BLOEDEL, Pres.