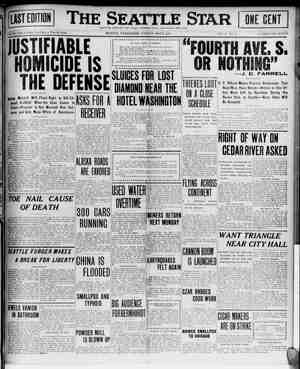

The Seattle Star Newspaper, May 8, 1906, Page 7

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

oti. ort. sty Paty the om at eard Per, hig fH TIKES | pul= ineas WASHINGTON May &—The 1 on Watson Os THE SEATTLE 4 Ol to crush out! | AN ASSAULT CHARGE AGAINGT JOHNG. N. Johna thant of giate under five different! . planting on, “which the report calla “pt ath, has rating,” and @etitious companies with tn which destroy competition by John hit and preveat Seal fade Nelson over the head with an axe adept ¢ snies from doing bue| tn a fiat xh Fenulted from 8 Aguinat Jamos Greene mittee on finance yes | “* mm wnaniine CASTRO IN LONDON LONDON May &—President Castro, of Veneauela, arrived here FUZZY WUZZY RUGS : nary : WASHINGTON, MAY Hen f congressional acti ad {nexpe- | tors Carter, Flint, Perkins and An pete fant your ter « made | dient consulted with Prest e We do both, Pussy! President Roosevelt signed the | Roosevelt today with reference Wurey Rug ¢ Queen Anne 1 Dill providing for a delegate to con ratiroad rate bill, The pre 1 » “ waa from Alash Jont sent for the me nat : WHY VITRIFIED STAR--TUESDAY, MAY 8, 1906. WASHINGTON, May &—~Preaident]own emplo .|BAN 1S PUT | ON PASSES 4 Washington Bidg 7? reasona ia, oo BRICK PAVEMENTS ARE THE BEST VALID, SELF-EVIDENT REASONS FOR THE CHOICE OF BRICK PAVEMENTS THAT APPEAL TO ALL First, because you can make choice of different kinds and methods of construction, ac- cording to conditions of use, nature of the soil in various localities, the local or nearby all details supplied or the least expensive and easiest manner of construction—the wante and needs of the largest cities down to the smallest of our villages. But whether a particular construction be chosen or not, brick streets meet conditions at either extreme-—you do not have to legislate against the use for which they were built, nor will they evaporate or rot | if not used at all. Equally good for heavy or light loads—-wide or narrow tires Second, they can be constructed at reasonable prices. No patent monopoly-—no secret process—the market is open and free competition afforded in every material entering into their construction. Vitrified brick are made by more than one hundred independent firms or corporations throughout the United States and there are more than one thousand contract- ing firms and corporations engaged in laying them. The actual first cost is leas than that of other pavements, prices ranging anywhere in the United States, with a few exceptions, at from $1.50 to $2.50 per square yard—method of con- struction, freight rates, cost of gravel, stone, sand, etc., being the factors regulating the exact figures at different places. Third, the methods of laying brick streets are so simple and easily understood that any property owner can know from observation whether or not his street is being built as it should be. Whereas in the case of other materials, there is a continued dispute as to which is | USES OF VIT The use of vitrified brick is not confined solely to the paving field but they are in con- stantly increasing demand for buildings of all kinds because of their impervious qualities and great crushing strength. They appeal to architects as they make a handsome wall, and to | owners in the matter of price. Nothing can compare with them for durability and strength, supply of sand, gravel and stone—requirements, taste or price. The most expensive with The street properly paved with them has yet to be excelled for wear, appearance and price. | TAXPAYERS the best mixture, or which method produces the best result. There is no dispute among brick manufacturers as to which is the best method of construction, and you can get carefully drawn directions for laying pavements from any one of them. It does not require the ser- vices of an expert to determine whether or not you are getting first-class vitrified brick, as is the case with some other materials, for the average man can, at a glance, distinguish a brick of poor quality and reject it, thus eliminating the liability of receiving poor material. You can know whether you are getting a good brick street while it is being built. With other kinds of streets you do not know for a year or more and it is then too late. Fourth, they are positively the most durable pavement of any in the world, and hence the cost of maintaining them is so small that this really presents the greatest reason of all why brick pavements are best. Constructed in the poorest possible manner they are far more durable than the best constructed of other kinds. We are now engaged in compiling reports from City Engineers of nearly 100 municipal- ities throughout the eastern, middle and centra! states, showing the vast amount of vitrified brick now being used for paving, not the least remarkable feature of these reports is the fact that the greatest amount of this work has been accomplished within the last decade. THERE IS NO TEST LIKE THE WEARING TEST and this tremendous amount of brick paving in recent years is attributed solely to their satisfactory experience with the few streets paved with this material in former years having been uniformly excellent. These re- ports are a splendid testimonial to brick pavements in every respect, durability, cost, sani- tary feature, easy maintenance, and will be published when compiled. IFIED BRICK They are used in every class of engineering work, bridges, culverts, sewers, foundations, in fact, every place where STRENGTH, IMPERVIOUSNESS and GOOD APPEAR- ANCE are needed. All authorities are unanimous in the opinion that the brick which we are manufacturing now at our Renton plant cannot be surpassed anywhere in the world. In conversation with Mr. R. H. Thomson, Seattle's City Engineer, he says among other things: “YOUR RENTON SHALE BRICK, UNDER THE TESTS WHICH WE GIVE THEM, DISPLAY SUCH REMARKA- <3 BLE TOUGHNESS IN CONNECTION WITH SUCH PERFECT HOMOGENEITY THAT IT WOULD SEEM IMPOSSIBLE FOR ANY BRICK TO BE MADE OF CLAY WHICH COULD EQUAL THEM.” No expense is being spared to make our new factory—now nearing completion—the model paving brick plant of the country. It will be thoroughly modern throughout, equipped with electricity. We have several carloads of machinery consisting of most advanced types of clay working machinery, ten induction motors, a Champion Rock Crusher, and a large | } | Worthington pump, capacity 600 gallons per minute, working against a 400-foot head. This + latter will give us complete fire protection and wil lalso be used for sluicing purposes. Against a capacity of 25,000 brick per day in the past, our new factory will turn out 50,000 to 60,000 vitrified brick, and 20,000 to 40,000 pressed brick PER DAY, which will enable us to carry a stock sufficient to meet all dermapds. The manufacture of high-grade red pressed brick is likewise going to be a FEATURE of this plant, and the superior quality and true shade of our output at this time augurs well for an enormous business in the future. THE RENTON PLANT. AS WELL AS OUR OTHER FACTORIES AND MINES, IS LOCATED IN KING COUNTY, WASHINGTON, AND IS DISTINCTLY A HOME INDUSTRY WISE RESIDENTS OF SE OUR EMPLOYES, NUMBERING ABOUT 500, ARE LIKE- TTLE AND KING COUNTY. EVERY PARTICLE OF RAW MATERIAL USED AND COAL CONSUMED IS DRAWN FROM COUNTRY ADJACENT TO SEATTLE, AND THE MONEY THUS EXPENDED REMAINS WITHIN OUR PORTALS; OR, IN OTHER WORDS, FROM THE MINING OF THE CLAY TO THE FINISHED STREET, EVERY DOLLAR PUT INTO A BRICK PAVEMENT REMAI NS AT HOME. Denny-Renton Clay and Coal Company SEATTLE, WASHINGTON iment to TEN NEW BCHOOLS. a tidings will be ed in th this #um according to County Superin nt Store Besides these in ments, there will be wlona mi on several bu Three new districts will be ope Cash Register Exchange WE BUY, SELL OR EXCHANGE CASH REGISTERS We pay bighe-t cash price fo Registers. The Sundwall Co. 609 Ist Ave. Phone 697