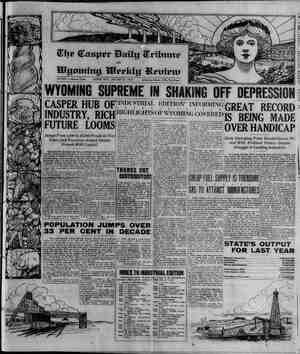

Casper Daily Tribune Newspaper, January 22, 1922, Page 19

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

SNDUSTRIAL EDITICN. TEN MILLIONS ENLARGING BIG REFINERIES Casper Becomes Largest Gasoline Pro-| ' ducing City of Nation as Result of ’ Enlargements Last Year ‘Casper, due to the expenditure of approximately $10,000,- 000 tm refinery construction programs during the year 1921, jumped to first place among the industrial cities of the country. rps te ris from the viewpoint of ulation Casper is of the eoush important industrial fa of the country, the products shipped from this city dur ing the year are said to have reached @ total of over $100,000,000 or an average of $4,000 for every man, woman and child, placing Casper’s population on basi¢ of 25,000 people. ‘This tremendous ‘incomne fs repre rented mainly in the sales sof gaso- Une, wax and other manufactureg pe- troleum products, which were placed on the commercial markets of the world by the Standard and Midwest | refining companies. ‘The major plant tn Casper during the past year wad the Midwest Re- fining company. This plant equipped cnly to bandle the crude olls and extract producte which are easily “cracked” in high grade petroleum, attained the position of the world’s greatest tndividua! gasoline manufac turing plant. \ Standard ReRuns OD. After the crude of ts run through the Midwest plant and all the extract- able products which that plant can cut are taken off, the off ia pumped to. the ftandard refinery, where through the agency of @ patented pressure refining the of] ts reduced to coke and all by-products removed with the lowest percentage ‘of loss. ty. Chats, Roe et ares. unferteken Ont he the latter of 1920, but ac- tual completion al: extension plans and the start of actual improvements, which placed the combined plants in the leading refining position, were handled during 1921. Midwest Spent Millons. cee ata ely 48,008,000 onthe tely $5,000. on ice taps 48 3 pen yg $1,000,000 In extending the Greybull plant and about $500,000 In doubling the ca- pacity of its plant at Laramio. ‘The Standard company’s plants known as a rerun plants which han- In Casper the expenditures of tho | the budget of $10,009,000 which rep- Standard are said to have totalled $5,000,000 and to have approximated the Midwest's ures of $1,000,- 000 at Greybull and $500,000 at laren to the extensions which were |! ma4e ‘during the year the Midwest compe y increased its capacity to 60, Darrels of off a day and tho Standard plant tncrenseq its charg- ing capactty to over 25,000 barrels a aay, Manufactured Output Doubled. In adition to {ts gasoline manu- facturing units the Midwest company made other vast extensions in its lubricating offs department and in other man sections of the giant plant. All departments of the institution were doubled by the com- pletion pros inaugurated dur ing 1920 end 1921, ry of ee leted during % aa enerteneal of the Midwest plant the big items of increase were sted as the increase in the crude oil running capacity to 50,000 barrels m @hy through ‘the erection of four batteries of crude stills. Hach of these batteries represented a unit of six stills, each still having a charg- ing capactiy cf 1,000 barrels of crude oil. In afaition to the crude ofl capac’ ity ‘extensions 1921 saw the comple tion of six lubricating: off stills, each of which have a capacity of 1,000 barrels. ‘These two effitions alone brought the ofl charging cxpactty of the plant to 60,000 barrels a day, a jump from $0,000 the former capacity charging basis, The crude run was thus in- creased 75 per cent and the tubricat- {ng off manufacturing department in- creased 100 per cent Departments Are Enlarged. Other plant extensions tnefutted doubling the capacity of thé wex pressing plant, one of the by-products of the lubricating ofls it. ‘The vast *product which ts secured from, this plant enters the world mar- ket dnd finds its largest demand in various parts of China. Shipments from Casper are forwarded direct to Hong Kong. For the first time in the history of a cess, Improvements made on the Sharpless patented process, by Rob- ert L. Spencer and O. A. Porter, both / members of the Midwest enginesring force alone made the process a com- mercial possibility. The Sharpless plant tg housed in the big brick building, one and two cfortes in height, which is erected North of the Yellowstons highway op- posite the plant henc.uerters. This plant performs ite refining function through the egency of 24 centrifuge machines which operate somewhat similarly to the principle| Number of enterprises ......5..0csceeeeeee of cream separators. Number of petroleum and natural ‘The naptha treating plant a contin- uous treating system erected et the Midwest during the past year has centages of the acid used tn of re Gning, wna erected during the past year. This plant avereges a recov- ery of about $5 tone of acid a day. Fuel Cost Big Item. From estimates nade on the cost of refinery operation fn the past year, during a greater part of which the plants were operated with fuel oil motive power, the fuel cost at times} exceeded 50 per cent of the total ex- pense of m«nufacture. This condi- tion ts sald ty hayp existed at both| the Standard and Midwest plants, ‘The figures invo:ved over half the! entire operating expense but are ex- clusive of the figures contained in| resented the extension and building budget of both plants. A large percentage of the exten- sion vperations of the Standard plant are taken up with the erection of a total of 60 stills. construction of in- eldental refinery contro) units and the replacement of worn units which in- cluded replacement of still boflers on batteries Nos. 1. 2. 3 and 4 of pres- sure stil? sections. Greybull Plant @xtensions. the Midwest company ry of six crude “stills with a capacity of 600 barrels e: and & battery of six coking onch of which also had a capacity of 1.000 barre!s. While completed the coking stills had not been placed in operation dur- ing 1921 but will be running off be- fore the end of January. These op- erations increased the capacity of the Midwest plant to 15,000 barrels of oil a day. In addition a 10,000-barrel capacity continuous treating naptha plant was erected. This doubled the capacity of the Midwest plant and cost about $1,000,000. The Standard company kept pace with the Midwest at Greybull and in- creased the capacity of its plant to handle the rerun olls from the Mid- west plant. The cost was contained the Burton process stills erected, and approximated the expenditure of the Miawest company. 2 Plants Doubled. A battery of six 400-barrel crude stills was constructed, doubling the capacity of the Midwest plant at Laramie, Under this extension the oll capacity of the plant was brought to @ total of 6,500 barrels of of] a day. Duplicating the work of the Midwest company the Standard dou- bide the size of its plant, the expen- diture almost equalling the $500.000 expenditure of the Midwest company. On OctobeF 1, 1921, the Standard Ol company (Indiana) through a contract with the Midwest Refining company took over the operation and management of the three Midwest plants in the Wyoming field. Later through 93 per cent stock ownership of the Midwest company, the’ Standard became the guiding genlus of the of! industry of Wyo- ming with approximately a 90 per pent control of the refining, producing and pipeline facilities of the state. Standard control of the Midwest company also places it in- control of the Utah Oil & Refining company, which operates a 5,000-barrel plant at Balt Lake City and scores of pro- ‘The only other enterprise of the Standard (Indiana) company in the state at this time is a refining plant now under construction at Glenrock whiah will handle the residue oils of the Mutual O0 & Refining company, which is controlled by the company through its stock ownership of the Midwest. : ‘When the Standard ‘company as- sumeéd contro! and operation of the Midwest plants at Casper, Greybull and Laramie, the management of the producing, pipeline and other depart: ments was left in the hands of for- mer Midwest company executives, With the Standard plants in Cas- per now operating at capacity of pipeline deliveries, it is probable that no appreviable additions will be made to the plants this year. Maintaining capacity production is assired however due to the fact that the Casper plants entered the world WE ALSO BUILD ful superivision. consult us as to your needa, 3 FP, L. MARTIN, 4 General Manager Office and Shop, Third and Conwell ¢ OSES ° < Yellowstone Bailing Company Are prepared to handle construction work in Casper during i927, with the best mechanics to be had in the city. and the most care- If you want the BEST when you build your HOM®, HOMES TO SELL Postoffice Box 1620 Phone 1410NJ have and power sold. market and were fortunate in secur- ing @ contract for delivery of 2.000,.-| tnyed by the Standard of Louisiana. 900 ‘barrels of high test gasoline,| iayed by the Standard of Louisiana to which will be shipped trom Casper to! England for trade purposes. THE CASPER DAILY TRIBUNE AND WYOMING WEEKLY REVIEW EXPENDED IN Complete figures as announced by the department of commerce follow: 1919 1909 Inc'e 9,514 7,193 260,673 166,320 125, 59,085 eas wells 14. 223,872,364 20,767,040 1,444,695 106,458,518 21,282,820 88,690,623 2,576,986 1,001,316.060 185,416,684 360,016,40C 694,107,677 172,559,394 $117,696,529 M. Cu. ft . 1,276,152.627 659,800,490 118.2 ‘Value at well +$ 155,847,006 § $7,065,397 180.0 Natural gas gasoline— Gallons ........ ++ 453,949,852 @) «.s- Value at plant . 78,752,824 @) ... 1—Minus sign () denotes decrease. 2—Not available. . 3—Includes gas purchased for use as materia) and for resale. 4—Includes value of minor products and amount received for work done Raton Rouge, La. and thence re ‘Independent Supply Co. _ Among the new wholesale institutions in Casper, is the Independent Supply company with offices and warehouses at 216 Industrial avenue. This company composed of local men, is incorporated under the Wyoming aws aaé have begun operations on a very large scale. The'r properties consist of a frontage of two hundred feet on Industrial avenue, with foun- dations in readiness for an additional four-story warehouse, which {s to be completed by early spring, This building will increase, by at least, five times thelr present floor space. The company’s trackage and loading platforms are fully adequate to handle their increasing large. business. Mechanical devices have been installed to facilitate the handling and moving of the heavier parts there- by elimi all truck and team hauling which is ordinarily a con- gene item of expense to concerns of this kind, nut so conveniently The advent of the firm into this “strict ts a distinct benefit not only to the public, but to“the larga operatiig companies and the many con- tractors, who have heretofore been obiiged to buy their supplies of bar iron and eteel outside the city, from Omaha and Denver, with the additional freight charges attached. the great saving buy Der tren: and steel, to the nm to consumer here, have been ht down at least 100 per cent since this firm began operating. ait’ The Independent Suppy company handles the famous products of the Jones Laughlin Steel company of Pittsburgh, conceded the best in the country and discriminating buyers secure these goods whenever possible. Two hundred and fifty tons of material including round and flat bar ‘iron and steel, tanks, and other products, listed below, are now on hand and several inore carloads are on the way and will be placed in trina as rapidly as the new warehouse is being equipped to care for ‘The tirm matntains @ completely equipped fabricati-z and general blacksmithing plant and any angles or shapes of bar fron and steel may be supplied without the expense of transferring. : The Independent Supply company is a welcome addition to Casper’s business institutions and their success is assured from the start. They are tors of the following high grade products: BESSEMER, BASIC OPEN HEARTH AND ACID OPEN BREARTH STEEL BAR MILL PRODUCTS Rounds Channels Tire Steel Bands and Hoops Half Rounds (Sq Twisted) Hexagons. aval (Diamond Bars) Special Shapes COLD FINISHED PRODUCTS Cold Finished Shafting and Screw Stock Flats l Harvester Shapes Zeo Bars Zees Ship Channets ON Well Casing On| Well ‘Tubing Pipe Dry Kim Pipe vi Brira Stews Pipe Taree 0. D. Pipe Tati Trrone, Fine 7 Deive-Pipe ne “rT” Ralls (8!!-40]) Track Spikes Boat Spikes Rattrond Track Drift Bolts Spikes ‘ RIVETS Boller Rivets Structural Rivets SEML-FINISHED PRODUCTS Billets and Blooms SInbs Skelp Sheet Bars WE INVITE YOUR INQUIRIES AND ORDERS - A -—TOOL COMPAN LEIDECKER PAGE THREE MANUFACTURERS OF OIL, GAS AND ARTESIAN WELL SUPPLIES Marietta Portable Drilling Machines Main} Office and Works _ Marietta, Ohio, U. S. A. BASIN, WYO. CASPER, WYO. Producers and Refiners CORPORATION FRANK E. KISTLER, Chairman of the Board WILLIAM L. KISTLER, President and General Manager Producer, Transporter, Marketer and Distributor of Petroleum and Natural Gas and Their Products. EVERY OPERATION ITS OWN FROM THE GEOLOGIST TO THE AUTOMOBILE Has Its Own Wells, Own Pipelines, Own Refin- eries, Own Tank Cars, Own Service Stations and Its Own General Office Building Has been a consistent operator in the Rocky Mountain Region and espe- cially in Wyoming, thus contributing to the growth and prosperity of the entire state. Has producing properties in Selt Creek, the: Osage, Lost Soldier, Mahoney Dome, Ferris, Lander and Sand Draw fields in Wyoming. Company supplies Riverton with natural gas from the big San Draw Field and the mammoth refineries at Casper with natural gas from the Ferris, Mahoney Dome and Lost Soldier Fields. Executive Offices—Denver, Colo. Division Offices—Yulsa, Okla., and Casper, Wyo. R. E. WERTZ, General Superintendent : : Western Division FOURTH FLOOR, MIDWEST BLDG., CASPER, WYO. a |. TreSPErrrTitirtrtr li i ttiittietr str itt ai Sa 9 $9600600664006666006600666660066660606666000600066606060666656 6000000000000000000000000000555b5bsbbbbbbbb»DAD000 on...