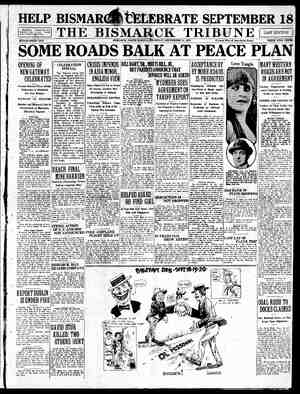

The Bismarck Tribune Newspaper, September 14, 1922, Page 17

You have reached the hourly page view limit. Unlock higher limit to our entire archive!

Subscribers enjoy higher page view limit, downloads, and exclusive features.

PAGENT EDITION SECTION III THE BIS K TRIBUNE PAGENT EDITION — SECTION II. BISMARCK, NORTH DAKOTA, THURSDAY, SEPTEMBER 14, 1922 COMPLETION OF $2,000,000 BRIDGE PROJECT ACROSS MISSOURI GREAT STRIDE FORWARD FOR ‘SLOPE’ NEW MISSOURI BRIDGE IS LINK OF NEW AND OLD WEST 4 v CITIZENS TURN BACK PAGES OF HISTORY IN BIG CELEBRATION; HONOR PAID TO HARDY PIONEERS Cities of Bismarck and Mandan Join in Celebration and His- toric Pageant as Tribute to Pioneers Whose Courage And Faith Made Possible Development of New $2,000,000 Bridge Project, Only Vehicular Bridge Across Missouri Between Great Falls, Mont. and Sioux > City, Ia, Again a vision of western faith and confidence in the!future has be- come a reality! For just as the sturdy pioneers who trekked the Great Plains and open ed to the world a new storehouse of treasures; just as the “empire build- ers” created a new epoch in transportation in the Northwest by pushing rails of steel ‘across a then barren Jang and solved the problem of bridging the barrier‘of the Missouri River, so have those who visioned the spanning of the “Big Muddy” for the benefit of a new mode of. transportation been imbued with a restless and unceasing spirit of advancement and achieve- ment. ¢ “And just as each big forward step in the development of a great terri- tory has provoked credulity and aroused doubt, so was the first suggestion that the broad Missouri be spanned with a great, free vehicular bridge here regarded ag an evidence of hope founded on fancy. Only a few short years ago to speak of the building of the new bridge was to provoke a knowing smile. The engineering problems met in, the shifting sands of the Missouri’s bed, the difficulties of. financing and the opposition of swirling currents and crushing ice floes all were ‘met and conquered before the North Da- kota Liberty Memorial: bridge ‘became an easy pathway from one shore of the river to the other. Many Citizens Worked Long and Hard For Bridge Just when the big bridge had its inception in the thoughts of forward looking citizens is difficult to say, but the expression of individuals was but a manifestation of the spirit which ever is alive in a young and growing region. It was only six or eight years ago when the ‘vision began to take the shape of an organized drive for the fulfillment of the big project. The first attempt was unsuccessful. Preliminary plans and an estimate of cost were asked. The project appeared staggering in view of the many problems. But the effort was continued and about 1918 a successful attempt. was made to secure authorization from Congress for the construction of such a bridge across a navigable stream. This authorization was given on February 27, 1919. It was necessary.that the plans be approved by the War Department. Formerly this department had required a clearance of 50 feet above the hichest water level of the navigation season. It was believed by many that this clearance was far greater than the present or prospective navigation needs demanded and movement was begun in 1919 to have this clearance re- quirement reduced. A hearing was held at Kansas City during the fall of that year and on January. 8, 1920, the War Department approved the pro- - posed plans showing a clearance of 38 feet, which gives a clearance of ap- proximately 55 feet at normal low water or a roadway height of 60 feet above normal low water.. This reduction in height of 12 feet has undoubt- edly detreased the necessary length of the approaches several hundred feet and for this and. other obvious reasons the cost was greatly reduced. , About the same time that effort was made for. authorization from Con- gress a-bill was.nggsedby-the Narth Dakota-lepislature which, appeared to:| authorize state aid in the amount of one-third to bridges located of the; state line or over a navigable stream. The legislature, however. failed to provide a fund that could be’ legally drawn for that purpose until the special |: session of 1919, when an appropriation of $225.000 was made. The sessién of 1921 made.an additional appropriation of $175,000.00, making available a total of $400,000 to meet the state’s share of the cost., This did not pre- vent preliminary action on the proposed bridge. Early in April 1919, nego- tiations were begun between the Counties of Burleigh and Morton. An interesting story is told by a local man of the passing of the bill permitting the state to aid in the construction of a bridge over a navigable stream. A bill had been introduced by a Grand Forks senator permitting the state to aid in building a bridge at the international boundary or .be- tween North Dakota and other states. This bill was carried to a Bismarck man by 2 Burleigh county member of the committee.’ He added the amend- ment, “or over navigable streams within the state.” This made it possible for the state to aid in building a bridge over the Missouri, and the senator who introduced the bill for the purpose of aiding a project in another part of the state was surprised to learn later that his bill made possible the bridge here. jon Burleigh and Morton Counties Make Bridgd Appropriations = On May 13, 1919, the Burleigh county commissigners -passed a resolution appropriating $90,000 to become avail A; i of $30,000 per year for the years beginning July 1, 1919, 1! y On May 6 of the same year Morton Later, these appropriations were in On May 19 of the same-y ceived at Mandan. Six or als from some of the best’ Kae purpose of this preliminary e proposed site or sites and fut factory to the State Highway C The C. A. P. Turner company. boards, the highway commission’ the structure and having inti engineer selected if same were Public Roads, which. was expect The general plans were # November of'that year and time plans had also“been submi proval which was obtained. With the plans finally sett May 14, 1920 was published, éallf basis and on a straight lump for the superstructure, the lo Company and to whom the col ceived on the.lump sum bai bids submitted on a sliding fe costs estimated for the work aj the Foundation Company. Thi The contract provided the Fot ment necessary in the const use of their organization and construction. For this they ated to a maximum and a‘m main river piers was $256,319.@% 500.00, making a total basic Comm crete approaches was .$280,119¢ $327,119.00. Their basic fee wage unit cost. Pe Contract For Co The contract provided contract estimate that 50 pe fee of the Foundation Comp reached on the four main $35,600.00. It also provided tang the estimated cost the fee: fp increased by 50 percent of. piers was reached and on. provided that increases in be carried for the same fee. «Under the terms of the iy American Bridge Company ment to the contractor of all ment in excess of what it we ing of the contract which The Foundation Company’ parties for the materials in’ market, no figures that were: would be made at those priges. When the legislature had: on the Highway Commissi most favorable conditions t¢ struction of the bridge. Th struction was specified b the end of that fiscal year Entire Project ‘Wi The ultimate cost of thes cause of interest charges original estimate. The similar appropriation. 0 by each county. $y engineering were re- fhich included propos- the country. The test borings over the that would be satis- u of Public Roads. lected by the county ept the plans of the tUmited States Bureau of the funds, Ly Commission during ymber 29. In the mean- rtment for their ap- Pie feat for opening of bids on (68 Wids-on a fixed sliding fee | lump bids were received m the American Bridge There were no bids re- ute; There were several of which, considering the e smallest fee, was from contract entered into. Hould furnish all equip- ‘and also the benefit and with a superintendent of ed fee which was gradu- imate of cost of the four ion this portion to be $39,- 00,| The estimate of the con- Wf; $47,000, making a total of 5 percent of the estimated of construction exceed the jould be deducted from the n figure of $30,900.00 was the concrete approaches of tk be completed for less than dation Company should be fximum of $48,100.00 on the es of $58,400.00, It also of 25 percent or less would an increase in the rates. gen prices secured from various ,Owing to the condition of the da guarantee that deliveries ey it became incumbent up- earliest time and under the of Federal Aid and the con- ‘of Nearly $2,000,000 yet actually determined be- sign specifications for |. . ao (3) End view of new bridge, whose spans total 1,800 feet long. (4) Ferryboat “Marion,” the only means of vehicular crossing, except on ice, until the new bridge was opened. (5) Old block house over-looking old ferry cressing in days of Indian uprisings. (6) General George Custer and of+ Key to pictures shown abo’ (1) New, bridge over Missouri riv- er at aMndan-Bismarck, N. D., which is to be formally dedi- cated September 18, 19 20. Built at a cost of $2,000,000 by-| S. Federal aid. (2) First railroad train of North- ern Pacific crossing river on ice Feb. 18, 1879. ‘a fase a) noe ficers of his command Seventh Cavalry, most of whom were killed two months after this picture was taken, in the battle of the Little Big Horn, Gatling gun battery used to clear the Missouri Slope of hostiles by forces at Fort Lin- coln, the first big outpost from which troops swept the red forces and possible. (8) General George Custer, massa- cred with his forces in Montana by the Sioux under Sitting Bull. Custer pictures copyrighted by aBrry, Superior, Wis., published through special permission. Persons shown in the Custer made settlement = George Custer; Lieut. Hodson; Mrs. George Custer; Mrs. Capt. Uates; rMs.: Calhoun; Lieut. Cal- houn; Lieut, Cameron; Colonel Carlin; Mrs, Moylan; Lieut. Cal- houn; Mrs. McIntosh; Capt. Moy- lan; Lieut. McIntosh. Seated, low- er steps: Captain Yates Miss An- nie Bates. Command group were right top: Capt. Wm. Thompson 7th Cavalry. Left to right top step: Mrs. Mac- Nougall, Capt. MacDougall, Lieut. Wm. Badger, Charlie Thompson, Lieut. Poland, Captain Tom Cus- ter, brother of the general, Gen- eral group, left to right: Lieut. Bronson, 6th Infantry, Lieut. Wal- lace Coakley, 7th Cavalry; Gen. Mandan and Bismarck, the bridge may well be called b $2,000,000 project. From the start of the work the usual difficulties were encountered by engineers but they also encountered difficulties which were extraordinary. In November, 1920, thé construction trestle which as erected as a cross- ing over the river was carried out by the ice breaking up in the river after it had been closed for weeks. This was the first time in the history of the local weather bureau that the river had broken up during the winter after having once been closed by ice. The trestle was carried away for the most part, a loss of $20,000 being sustained. This loss also delayed work on the | bridge about forty days. Another trestle was placed which was used until the ice broke up in the spring of 1921. Unfavorable weather, together with unlooked for delays, prevented the finishing of the work by the time the ice went out, also earlier than usual. Most of this trestle was saved. An- other trestle was completed and an) unusually high June rise ‘carried this out with considgrable Joss, the detail loss occasioned by'the three accidents amounting in excess of $30,000. Many persons casually crossing the new bridge may not appreciate its immensity. The ebridge and approaches are 2,543 feet in length, almost a half a mile. The roadway on the bridge is 70 feet above the water. The topmost point on the bridge is 120 feet above the water. An interesting method of putting down the piers was adopted. Because of the shifting sands in the bottom of the Missouri, and the fact that the current is continually digging downward, it was necessary to go deep into clay for the foundation of the bridge. Interesting Method is Used in Putting Down the Piers. The engineers employed the open-w@ll method of putting down the piers. However, the west shore piers, though like the others sunk by the open-well procedure, were sealed in the clay in the dry. This was insisted upon by the United States Bureau of Public Roads. In order that the read- er not versed in the technic of engincering may have a clear understanding of the process, it will be safe to set forth briefly the general method. It is customary to contruct a ring of steel or other material. placed on the exact/site wherc the proposed shaft is to be’ sunk. The un- derside of this ring will usually be provided with an edge consisting of a single bevel; much like the edge of a tile. @rical wall. Thus, this tile-shaped structure is placed on the bed of the river. By digging round and round the edge, from the inside, the cutting edge of this “tile” of masonry may be made to descend of its own weight. If | point to about 6 feet above low water the pier is somewhat in the shape of | This is built or | This ring is the cutting edge. | Above and on this ring is constructed of concrete or other masonry a cylin- | the soil penetrated carries water in any considerable quantity, this may give too much trouble to permit one to rely simply upon pumps, As this “tile” or “well” sunk of its own weight when earth was taken out from the inside, another section was placed on top of it, and another, and so on until the several sections, fastened together as one, had sunk to the complete depth of the pier, or about 50 feet. As the “tile” or “well” went down deeper the air became poorer. Water must be pumped out while the digging goes’ on. The “well” could be made airtight, and mén would work inside of it shovel- ing out dirt and manning the pumps under compressed air. The tension of the air in this process is so managed as to prevent the entrance of water through the bottom of the shaft or around the cutting edge. In short, the interior is kept dry, thus permitting workmen—sand hogs—to dig away the earth at the bottom and so allow the well to settle further and further down. Or the pier may be sealed “in the wet,” that is, water being allowed to seep inside. Compressed Air Method Used and Sand Hogs Imparted Under the compressed air method, which was adopted on the west shore piers, the air tension is so great that men can work only for limited peri- ods. Often when they are taken out they are placed in a great boiler which | and it is gradually reduced until their respira- | has the same air pressur tion becomes normal. This big boiler which was maintained to the bridge here was‘riick-named the “cast iron hospital.” under compressed air were brought to Bismarck from the south to do this work. After these tile-shaped, hollow shafts were sunk the full depth, rocks and concrete were poured in them, until the pier was made one solid mass. The shore piers consist of two cylinders with bases 20 fect in diameter and 10 fect in height. From this point to slightly above low water level the piers are continued as cylinders 14 feet in diameter, these being connected at their base by a girder 9 feet in thickness and 12 fect in height, and also connected near their tops by an arched web. The base of the eastern shore pier is Jocated about 43 feet below normal low water and about 103 feet be- low the roadway of the bridge. The case of the western shore pier is lo- cated about 75 feet below normal low water and 139 feet below the road- way. Thus the bridge, including this pier, is over 200 feet in height, or higher than many buildings called sky-scrapers. The main river piers have rectangular bases 23x60 feet and 14 feet 6 inches in height. Above this Two courses were open. | Negroes who had worked | | | a flatiron, the general dimensions being 16 feet in, width by 60 feet in | length. Above this point the thickness of the structure is reduced to 12 | feet. The point, or up-stream edge, is gradually battered or sloped to pro- vide an ice cutter or breaker. This section of the pier is 18 feet in height. From this point the structure is continued as two cylinders 10 feet in dia- | meter, which in turn are connected at the tops by an arched web. Bridge 170 Feet High Pier Bottom to Topmost Point The base of the eastern river pier is about 41 feet below normal water level and 101 feet below the roadway. The base of the western river pier is upproximately 74 feet below low water level.and 134 feet below the roadway. The main bridge is reached by means of ‘two curved reinforced con- crete approaches, the east approach being 480 feet in length and the west one 625 fect, making a total length for the structure of 2,548 feet, or 92 feet less than half a mile. The approaches are girded on either side by | North Dakota made brick. | The bridge itself consists of three main spans of total length of 1,443 feet. The trusses adopted are known as the Warren-Turner type. The top of the great steel trusses, into which were driven 80,000 steel rivets, is 70 feet above the bridge roadway. The roadway on the bridge is 26% feet between curbs and on the ap- proaches 26 feet in width. Besides this roadway, two sidewalks about four feet four inches in width are provided. The roadway and sidewalks on the steel spans are. of reinforced concrete, and the entire roadway is surfaced with 1% inches of asphalt. At times during the construction as many as 250 men were employed at one time, and operations were carried on both day and night, The bridge has been officially named the North Dakota Liberty Mem- |orial Bridge in honor of the North Dakota soldiers who served in the World War. A tablet placed on the bridge bears the names of the members of the state highway commission and boards of county commissioners of Burleigh and Morton counties during the time the bridge was named: They are Gov- ernor Yynn J. Frazier, Governor R. A. Nestos, J. N. Hagan, Herman Hardt, Frayne Baker, Benton Baker, Joseph A. Kitchen and W. H. Robinson, chief neer and secretary; Burleigh county board, Edward G. Patterson, ¢ man; Grant Palms, Chas. A. Swanson, Clement L, Malone, Victor D. Moynier; Morton county, C. B. O'Rourke, chairman; Theo. Feland, Aug. Nickel, D. M. O’Neil, G. H. Urban. C. A. P. Turner of Minneapolis was con- sulting engineer and Capt. I. P. Baker donated the right-of-way land for (Continued on page 6)